What is the VHP Passbox?

The VHP (Vaporized Hydrogen Peroxide) Pass-Through Window is primarily utilized for the biological decontamination of materials’ outer surfaces, preventing contaminants from entering high-level areas from non-classified or lower-classified zones. This system employs an external hydrogen peroxide generator (VHPS), operating under low-temperature and standard pressure conditions, ensuring an environmentally friendly and efficient decontamination process.

QUALIA vs. OTHERS

| Feature | Qualia | Competitor |

|---|---|---|

| Sterilization Time | Minimum of 30 minutes | Minimum of 120 minutes |

| Seal Integrity | ±2000Pa with decay less than 0.5% Vol/h over 20 minutes | 100Pa not exceeding ≤0.5% Vol/h |

| VHP Generator | Complete dry vapor, multi-channel labyrinth module | Aluminum flash evaporation dish, square or cylindrical type, incomplete vaporization, prone to condensation and dew formation |

| Mechanical/Inflatable Seal | EPDM (Ethylene Propylene Diene Monomer) 6±5°shoreA | Silicone Rubber |

| Seal Service Life | ≥5 years | ≤1-3 years |

| Seal Strip Corner Radius | R95 | R100 |

| VHP Weighing Sensor | Gravity sensor | Low accuracy electronic scale |

| Air Supply and Exhaust System | Independent duct system | Room air intake; may affect room pressure if space is too small; in case of malfunction, VHP may leak into room |

Product Features

Pneumatic Seal APR Door

Hidden inflation tube

with Pneumatic Seal APR Doors

on Fair

- Sealing Performance: Achieves biological safety standards with pressure decay of less than 0.5%Vol/h at ±2000Pa over 20 minutes.

- Sterilization Efficiency: The entire sterilization cycle (including residual removal) takes as little as 30 minutes, shortening processing time by 50%-70% compared to similar market offerings.

- VHP Generator: Utilizes complete vaporization with a multi-channel labyrinth module to prevent condensation and fogging during sterilization.

- The Seal Door Types of VHP Passbox: Available in inflatable seal and mechanical compression styles, with the inflatable variant featuring high-density EPDM imported from the Netherlands, rated at 60±5° Shore A, and hinges cleverly concealed.

- Door Handles: Designed for both inflatable and mechanical pressure models. Inflatable pressure model includes a protective handle to prevent accidental pressure rebound injuries. Mechanical pressure model is crafted from durable SUS304 stainless steel through CNC machining for longevity, strength, and fatigue resistance.

- Liquid Weighing: Employs a gravity sensor for precision measurement and can be set and adjusted according to specific usage.

- Communication with BMS Systems: Capable of online and remote printing, as well as data storage.

- Temperature Stability in Sterilization: Minimal change, with an optional configuration keeping within ≤3℃, ideal for sensitive biological transfers like serum.

- Independent Air Supply and Exhaust: Built with standalone air ducts, the unit comprises integrated supply, exhaust, and recirculation fans and can connect to customer HVAC systems.

- Functional Versatility: Equipped with a feature switch that toggles between VHP sterilization transfer mode and standard self-cleaning UV sterilization transfer mode, selectable via touchscreen (optional configuration).

- Sturdy Door Construction: Both sides of the door are made from fully welded 3.0mm stainless steel sheets, with built-in double-layer 5mm tempered glass.

- Safety Assured: Rounded corner welding and comprehensive sanding ensure safe use and mitigate collision risks that could lead to glass breakage.

- Built-In Biological Safety Valves: Internally equipped with airtight butterfly valves to minimize the risk of hydrogen peroxide leakage during sterilization.

Technical Specifications

- Power Supply: Operates on a single-phase AC 220V/50Hz power source.

- Efficiency Level: Supply air features HEPA H14 filtration; exhaust air also utilizes HEPA H14 filters.

- Sterilization Temperature: The temperature range for sterilization is between 18-35°C.

- Sterilization Pressure: Operable at 0-100Pa for sterilization processes.

- Decontamination Cycle Time: Less than 120 minutes to complete a decontamination cycle.

- Inflation Pressure & Timing: Achieves an inflation pressure of 1.5kg/cm2 with inflation and deflation times of less than 5 seconds, capable of more than 10,000 cycles without bursting or leaking.

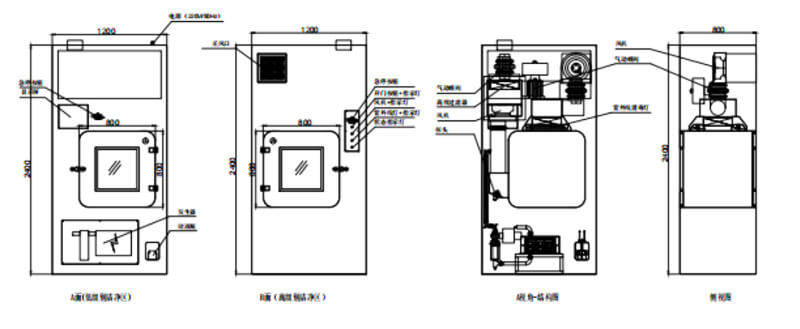

Different Types of VHP Passboxs

| Model | Inner Chamber Size (mm) | Overall Dimensions (mm) |

|---|---|---|

| MUO-060060060 | 600 x 600 x 600 | 1200 x 2400 x 600 |

| PFV-080080080 | 800 x 800 x 800 | 1400 x 2600 x 800 |

| MUV-100100100 | 1000 x 1000 x 1000 | 1600 x 2800 x 1000 |

Note: The aforementioned are standard specifications. Custom dimensions are available upon request.

Specification Model Index:

- M: Mechanical sealing

- P: Inflatable sealing

- F: Equipped with a fan

- U: Without a fan

- V: Integrated VHP (Vaporized Hydrogen Peroxide)

- O: External VHP connection

- D: Includes the dunk tank

VHP Pass Box Gallery

QUALIA VHP Passbox with Pneumatic Seal APR Doors on Fair_1

QUALIA VHP Passbox with Pneumatic Seal APR Doors In-build VHP_1

QUALIA VHP Passbox with Mechanical Seal APR Doors _1

QUALIA VHP Passbox with EPDM Pneumatic Seal Gasket_1

QUALIA VHP Passbox with dynamic validation use Hidden inflation tube Pneumatic Seal APR Door_1

QUALIA VHP Passbox with dynamic validation use Hidden inflation tube Pneumatic Seal APR Door On Site_1

QUALIA VHP Passbox Pneumatic Seal APR Door In-build VHP UV Lamp Anti-UV Glass_1

QUALIA VHP Passbox in Factory_1

QUALIA VHP Passbox _1

Related Contents:

- Double-Chamber VHP Passbox: Enhancing Efficiency and Flexibility

- Navigating Biocontainment: The Critical Differences Between BSL-3 and BSL-4 Labs

- Ensuring Safety with Bag-in/Bag-out: The Definitive Guide to Hazardous Filter Replacement

- What is the process of bag in bag out?

- What is the HS Code for “Bag in Bag Out”?

- Understanding the Differences Between Stationary and Mobile BSL-3/BSL-4 Laboratories

- Introducing Qualia: Advanced OEB5 Grade Protection with Bag-In Bag-Out (BIBO) System

- Introducing Our Custom-Designed Dry Isolation Weighing Chamber for European Clients

- Join Qualia at ACHEMA 2024 in Frankfurt, Germany