What is the Bio-safety Isolation Damper?

The Bio-safety Isolation Damper serves a critical role in modulating or halting airflow within a system to mitigate the risk of pathogenic microorganism leakage. The dampers are categorized into manual and electric types based on their actuation mechanism. The electrically operated isolation dampers can automatically regulate airflow in conjunction with a control system, ensuring air-tightness even in the event of power failure.

Compliant with ISO10648-2 “Containment enclosures – Part 2: Classification according to leak tightness and associated checking methods” and GB 50346-2011 “Technical specifications for biosafety laboratory construction”, these dampers are tailored to meet diverse user requirements and come in both circular and rectangular shapes. Moreover, the dimensions of the airtight valve can be customized to accommodate the specific needs of customers.

Product Features

- Air Tightness: At a pressure of ±5000Pa, the leakage rate does not exceed 0.25% of the net volume per hour.

- Pressure Resistance: The valve box can withstand a pressure of -5000Pa for 60 minutes without permanent structural deformation.

- Service Life: After 10,000 cycles of opening and closing, the valve passes the air tightness test under positive and negative pressure, complying with national standards.

- Corrosion Resistance: All components of the valve can withstand the corrosion of disinfectants such as hydrogen peroxide, chlorine dioxide, and formaldehyde. After the corrosion test, air tightness still meets national specifications.

- Resistance: With the valve fully open at the rated airflow, resistance does not exceed 40Pa.

Square Biosafety Sealed Value

| Model | Inner diameter | Depth | Axial length | Flange width | Flange Thickness |

| QL-VF-I | 250*320 | 300 | 395 | 50 | 5 |

| QL-VF-II | 320*500 | 300 | 495 | 50 | 5 |

| QL-VF-III | 320*800 | 500 | 695 | 50 | 5 |

| QL-VF-IV | 630*800 | 500 | 895 | 50 | 5 |

| QL-VF-V | 500*1000 | 500 | 1195 | 50 | 5 |

| QL-VF-VI | 630*1200 | 500 | 1295 | 50 | 5 |

Circular Biosafety Sealed Value

| Model | Inner diameter | Depth | Axial length | Flange width | Flange Thickness |

| QL-VY-I | 500 | 300 | 695 | 50 | 5 |

| QL-VY-II | 600 | 300 | 795 | 50 | 5 |

| QL-VY-III | 700 | 500 | 895 | 50 | 5 |

| QL-VY-IV | 800 | 500 | 995 | 50 | 5 |

| QL-VY-V | 1000 | 500 | 1195 | 50 | 5 |

| QL-VY-VI | 1200 | 500 | 1295 | 50 | 5 |

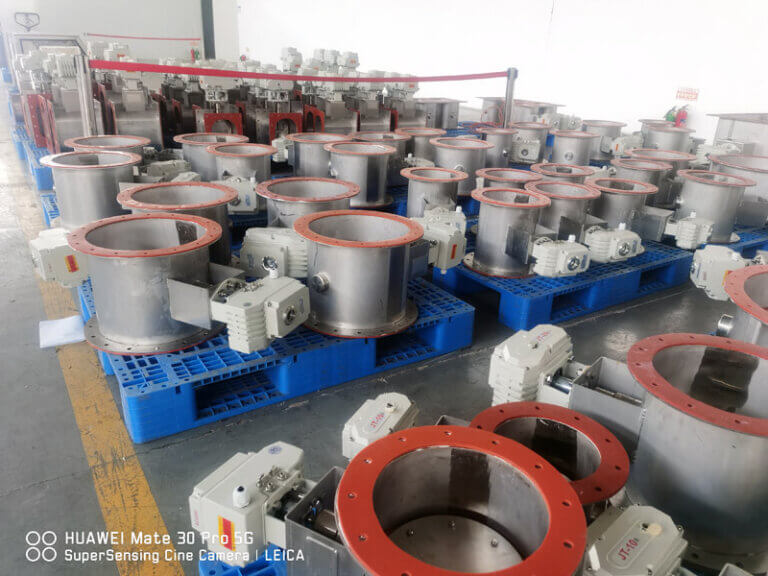

Bio-safety lsolation Damper Gallery

Related Contents:

- Navigating Biocontainment: The Critical Differences Between BSL-3 and BSL-4 Labs

- What is the process of bag in bag out?

- Double-Chamber VHP Passbox: Enhancing Efficiency and Flexibility

- Ensuring Safety with Bag-in/Bag-out: The Definitive Guide to Hazardous Filter Replacement

- Introducing Qualia: Advanced OEB5 Grade Protection with Bag-In Bag-Out (BIBO) System

- What is the HS Code for “Bag in Bag Out”?

- Understanding the Differences Between Stationary and Mobile BSL-3/BSL-4 Laboratories

- Introducing Our Custom-Designed Dry Isolation Weighing Chamber for European Clients

- Join Qualia at ACHEMA 2024 in Frankfurt, Germany