What is the Chemical Shower?

The chemical shower system is designed for use in special environments to ensure that personnel exiting high biological risk areas into negative pressure zones (toxic areas) undergo mandatory showering measures. This design is specifically for use in BSL-3 and BSL-4 (Biosafety Level 3 and 4) laboratories. The system features a high degree of automation, strong isolation capabilities, and a focus on the comfort and physical sensations of the workers. Qualia team has conducted a systematic design according to current national biosafety standards.

Product Features

The chemical shower system, designed for advanced-level biosafety laboratories, consists of a comprehensive structure made from stainless steel, including walls, floor, ceiling, ventilation systems, water supply and drainage systems, biological airtight doors, life support systems, mixed-liquid storage systems, mandatory control and safety systems, and a differential pressure system. Key components and features include:

Stainless Steel Main Structure: Utilizing a modular, integral design made from SUS316 stainless steel with a thickness of 1.5mm. To ensure the structure’s strength, custom stainless steel reinforcements and full-weld constructions are used internally, along with an aluminum honeycomb structure to ensure flatness, structural integrity, and airtightness.

Ventilation System: This system controls the air exchange within the shower unit to ensure a comfortable indoor environment for the human body. The air supply and exhaust volumes are determined by the size of the unit and are directly connected to the workshop’s main ventilation system, equipped with waterproof filters. Our team has designed various technical solutions such as top supply with top exhaust or top supply with side exhaust, considering maintenance convenience and airflow dynamics based on their extensive experience.

Water Supply and Drainage System:

- Spray head design

- Mixing ratio

- Water supply pressure

- Drainage system

- Human comfort

- Mandatory water supply program

Design and Performance:

- Modular design for easy installation and maintenance.

- Constructed with stainless steel for high seal integrity and strong compression resistance.

- Excellent airtightness: Air pressure within the enclosure decreases from 500 Pa to less than 250 Pa within 20 minutes.

- The structure withstands up to 2500 Pa pressure.

Functionality and Usage:

- The equipment is always ready for use, with no waiting time, supporting two individuals in positive pressure protective suits simultaneously.

- Features automatic liquid mixing, medicated showers, cleaning, and manual emergency spray options.

- Wide compatibility with chemical agents, including peroxide-based disinfectants, chlorine-based disinfectants, acidic oxidizing water, and commonly available disinfectants.

Safety and Communication:

- Equipped with double airbag inflatable airtight doors for onsite airtightness verification and enhanced safety.

- Multifaceted safety escape design, with time settings and escape protocols adhering to national standards.

- Capable of diversified communication with BMS systems based on client needs.

Technology and Innovation:

- Extensive experience in designing multifaceted systems.

- Possesses unique patented spray nozzles.

for easy drainage without dead angles

Control and Safety System:

- Mixing Ratio Control: Using European technology for precise control over the mixing process to ensure the solution meets the set program.

- Interlock Control: Beyond simply locking the doors, the system must synchronously operate with the mixing, pressure, and safety systems in real-time.

- Personnel Management: Implements fixed management methods for the shower system, with three levels of management permissions for controlled access.

- Time Control: Divided into preparation time for the shower system, mandatory showering time, and standby time.

- Alarm Control: Equipped with an alarm device for real-time alerts in any abnormal situation (such as issues with mixing, pressure, timing, or operation) and integrated with the central control system.

- Operation Record Inquiry: Features a Siemens touchscreen for real-time monitoring of system operations and status, also linked to the central control system.

- Emergency Escape System: Provides an emergency escape function to protect users and the equipment itself in any urgent situations.

- Data Transmission: Mainly interfaces with the central BMS system for coordinated control.

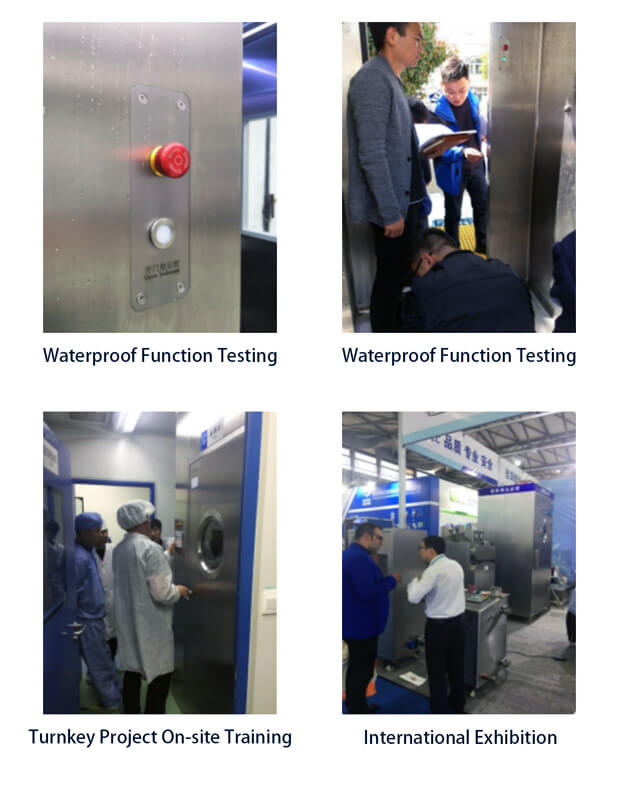

QUALIA's QC

The QUALIA’s team maintains strict standards for production processes and pre-shipment inspections to ensure product quality: using high-quality raw materials coupled with rigorous incoming inspections, strictly adhering to SOP management throughout the production process with comprehensive tracking inspections, having clear production procedures with accountability documented down to the individual, employing a professional self-regulation team to simplify processes and customize functions, and conducting destructive self-inspections before shipment.

Related Contents:

- Ensuring Safety with Bag-in/Bag-out: The Definitive Guide to Hazardous Filter Replacement

- Double-Chamber VHP Passbox: Enhancing Efficiency and Flexibility

- Navigating Biocontainment: The Critical Differences Between BSL-3 and BSL-4 Labs

- What is the HS Code for “Bag in Bag Out”?

- Understanding the Differences Between Stationary and Mobile BSL-3/BSL-4 Laboratories

- Introducing Qualia: Advanced OEB5 Grade Protection with Bag-In Bag-Out (BIBO) System

- Introducing Our Custom-Designed Dry Isolation Weighing Chamber for European Clients

- What is the process of bag in bag out?

- Join Qualia at ACHEMA 2024 in Frankfurt, Germany