What is the Water Shower?

The water shower system is implemented in specialized environments to ensure individuals’ physical adaptability and safety when exiting negative pressure areas (contaminated zones) within high biological risk regions. A water shower, in industrial or cleanroom contexts, is a system designed to remove contaminants from personnel or equipment before they enter a controlled environment. It uses high-pressure water streams or mists to clean off dirt, dust, or other particles to maintain the cleanliness standards of the cleanroom or sensitive area.

Product Features

- Innovative Manufacturer: First one in China to develop and produce mandatory shower systems; dominates the market with a 99% share of modular shower units, achieving sales of over 400 units in five years.

- Economical Water Usage: Utilizes a mere 12 liters per minute with uniform flow in both main and auxiliary showers, preserving the water supply.

- Pressure Measurement: Equipped with differential pressure gauges on both sides of two doors, with pre-set absolute and relative pressure ports.

- Optimized Air System: Features upflow with side return; high-efficiency filters on top prevent water interference during showers. The return air vent is designed at a 45° angle to facilitate water return and simplify duct cleaning.

- Independent Water System: Boasts a separate mixing tank for the water system, detached from the main unit to simplify servicing and upkeep.

Different Types of Water Shower

- Three Configurations Available:

- C-Standard Type: Waterproof doors on both sides.

- SA-Biological Protection Type A: Single-side APR door, with a waterproof door on the opposite side.

- SB-Biological Protection Type B: APR doors on both sides.

- Two Heating Methods Offered:

- EW-External Hot Water Piping: Connects to an external hot water supply.

- IH-Built-In Instant Heating: Features a built-in device for immediate water heating.

Constitutive Structure

- Composition

The Forced Water Shower System is constructed for high-level biosafety laboratories and includes a complete stainless steel framework, floor plate, top plate, air supply and exhaust system, water supply and drainage system, waterproof door, mandatory control and safety system, and a differential pressure system.

- Stainless Steel Main Structure: Our approach utilizes an integrated modular system made from SUS304 stainless steel, with a thickness of 1.2mm shaped through a comprehensive pressing process. To ensure the structural integrity of the unit, we reinforce it internally with custom stainless steel components and fill it entirely with a fireproof aluminum honeycomb structure to maintain the equipment’s levelness and strength.

QUALIA's Advantages

- Modular Design: Easy installation and convenient maintenance.

- Ready to Operate: The equipment is always on standby, eliminating wait times.

- Pioneering in China: The first manufacturer to develop water showers, with comprehensive experience in multi-system design.

- Customizable Communication: Ability to diversify communication with BMS systems based on client requirements.

- Water Temperature Precision: Control accuracy within ±0.2 ℃.

- Safety Escape Design: Incorporates multiple safety factors for emergency evacuation.

- Patented Nozzle Technology: Ensures comfort and effectiveness during showers.

- Compliance with Regulations: Time settings, temperature control, and safety escape mechanisms meet national standards.

QUALIA's Solution of Water Shower

System Solution Overview:

- Water Flow Control: The forced shower water system focuses primarily on the control of water flow, temperature, and drainage, operating as a separate, integrated unit.

- Showerhead Configuration: Equipped with three showerheads—one main and two auxiliary—designed according to forced shower standards while considering user comfort. This arrangement ensures uninterrupted showering and prevents any impact on the broader system’s flow and water pressure. Additionally, it eliminates any interior spray blind spots.

- Custom Water Temperature Control by QUALIA: Guarantees rapid achievement of the set temperature with a variance of less than 1°C. It ensures stability in water temperature even when public system supply varies, preventing any sudden temperature fluctuations.

- Sloped Base Design: The shower base is crafted with an angled design, eliminating cleaning blind spots and preventing water accumulation. The floor drain features a custom design that ensures complete drainage into the designated outlet, with no leaks.

Air System Solution:

- Ventilation Control: The air system regulates the number of air changes inside the shower unit through the air supply and exhaust systems, ensuring a comfortable indoor environment and optimal human comfort based on the unit’s volume to determine the necessary airflow rates for both supply and exhaust.

- Unidirectional Flow Structure: The interior of the forced shower system is designed for unidirectional flow, where the air enters from the top and is channeled back out through the top to the external exhaust system.

- Integration with Workshop Systems: The air supply and exhaust are directly connected to the workshop’s central air systems and must be fitted with waterproof filters to mitigate maintenance requirements and meet technical airflow pattern standards. Drawing from past experience and considering varying site-specific requirements, the QUALIA team has developed solutions like top supply with top exhaust and top supply with side exhaust.

Differential Pressure Monitoring:

- Transducer Installation: The forced shower system includes a differential pressure transducer to monitor the pressure difference across high-efficiency filters.

- Electronic Gauges: Electronic differential pressure gauges are installed on both sides of the system and must have transmission capabilities to monitor the pressure difference with adjacent rooms.

- Pre-configured Ports: The equipment is pre-fitted with ports for both relative and absolute pressure measurements.

Automated Control Solution:

- Human-Machine Interface: The system incorporates a Siemens LCD touchscreen from the Smart Series 700ie, with the PLC using the Siemens 200 Smart series or higher.

- Enclosure Location: Positioned within the technical interlayer, the enclosure houses all components and electrical equipment. Control functions are carried out by the control unit (Siemens programmable relays).

- Low-Voltage Wiring: All control wiring utilizes a low voltage control system, with voltages ≤36V.

- Wire Identification: Each wire is clearly marked at both ends with numbers, letters, or other identifiers, maintaining consistent labeling at all endpoints and junctions. Wire identifications are printed on oil-resistant and moisture-proof shrink labels.

- Mounting System: Terminal blocks and components are installed on the electrical panel using DIN rails for secure placement.

Temperature Control Strategy:

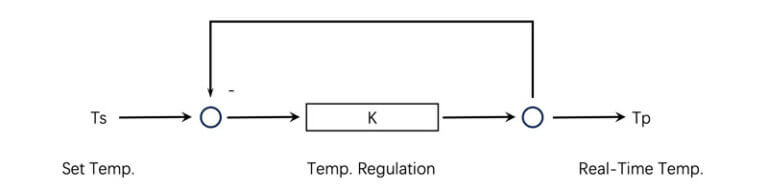

- Utilizes European technology for the water temperature control system which employs a closed-loop method, ensuring a constant output water temperature.

- This system maintains the water temperature independent of seasonal weather changes and provides real-time monitoring to ensure temperature accuracy.

Temperature Control Strategy:

- Utilizes European technology for the water temperature control system which employs a closed-loop method, ensuring a constant output water temperature.

- This system maintains the water temperature independent of seasonal weather changes and provides real-time monitoring to ensure temperature accuracy.

PLC Control Strategy:

- Layered Access: The system features four levels of access permissions, enabling the customization of primary and auxiliary showerhead drainage times, spray times after reaching the set temperature, intervals between each shower, cold water purge duration, waiting times post-shower before exiting, and the number of cycles.

Integration with BMS:

- System Communication: The forced shower system is designed with reserved points for communicating with the central control system, which can display the real-time status of the shower system and the doors’ open/close states.

- Data Access: Operational data and equipment status can be checked in real-time on the screen and is linked with the central control system. However, the central control system does not have the capability to issue direct commands to the equipment.

Alarm Controls:

- Alert System: Equipped with a dedicated forced shower alarm device that triggers real-time alerts in the event of any anomalies (such as irregular water temperature, pressure, time, or operator errors) and is linked with the central control system for integrated notifications.

QUALIA's QC

The QUALIA team has strict requirements for production processes and pre-shipment inspections:

- High-quality raw materials and rigorous incoming inspection.

- Strict implementation of SOP management throughout the production process, with full tracking inspection.

- Clear production procedures, with accountability recorded at the individual level.

- A professional self-control team, with simplified procedures and personalized functions.

- Disruptive self-inspection before shipment.

Water Shower Gallery

QUALIA Water shower

QUALIA Pneumatic Seal APR Door water shower

QUALIA Water Shower

QUALIA QUALIA Water Shower

QUALIA Full welding SS lab VHP pass box Water shower APR doors

QUALIA 6m water shower

QUALIA Water Shower

QUALIA Water shower

QUALIA Water shower

QUALIA BSL 3 Module Laboratory with water shower_1

QUALIA BSL 3 Module Laboratory inside View with Water Shower and In Situ Filtration System and Biosafety Passbox_1

QUALIA Water Shower SAT test on site 2_1

QUALIA Water Shower SAT test on site 1_1

Related Contents:

- Double-Chamber VHP Passbox: Enhancing Efficiency and Flexibility

- Ensuring Safety with Bag-in/Bag-out: The Definitive Guide to Hazardous Filter Replacement

- Navigating Biocontainment: The Critical Differences Between BSL-3 and BSL-4 Labs

- Understanding the Differences Between Stationary and Mobile BSL-3/BSL-4 Laboratories

- Introducing Qualia: Advanced OEB5 Grade Protection with Bag-In Bag-Out (BIBO) System

- What is the HS Code for “Bag in Bag Out”?

- Introducing Our Custom-Designed Dry Isolation Weighing Chamber for European Clients

- What is the process of bag in bag out?

- Join Qualia at ACHEMA 2024 in Frankfurt, Germany