Biosafety Level 3 (BSL-3) laboratories are critical facilities designed to handle dangerous pathogens and conduct high-risk biological research. The layout and design of these labs are crucial for maintaining safety, preventing contamination, and ensuring the protection of both laboratory personnel and the environment. As the complexity of biological research increases, so does the need for well-designed BSL-3 facilities that meet stringent safety standards and regulatory requirements.

The design of a BSL-3 lab is a complex process that requires careful consideration of numerous factors, including airflow management, containment strategies, and personnel safety protocols. These laboratories must be constructed to prevent the release of potentially harmful microorganisms and protect researchers from exposure to infectious agents. The layout must also facilitate efficient workflow while maintaining strict biosafety measures.

In this article, we will explore the essential layout requirements for BSL-3 laboratories, examining the key components that make these facilities safe and effective. From the basic floor plan to specialized equipment placement, we'll delve into the critical aspects of BSL-3 lab design that ensure both safety and functionality.

BSL-3 laboratory design is a highly specialized field that demands meticulous attention to detail and adherence to strict safety protocols. The layout of these facilities must incorporate multiple layers of containment, advanced air handling systems, and carefully planned workflow patterns to minimize the risk of exposure to hazardous biological agents.

As we navigate through the intricacies of BSL-3 lab layout requirements, we'll address several key questions that are crucial for anyone involved in the planning, design, or operation of these high-containment facilities. Let's explore the essential elements that make a BSL-3 laboratory both safe and efficient.

What are the fundamental principles of BSL-3 lab layout?

The foundation of any BSL-3 laboratory design lies in its adherence to fundamental principles that prioritize safety, containment, and efficient workflow. These principles guide every aspect of the lab's layout, from the overall floor plan to the smallest details of equipment placement.

At its core, a BSL-3 lab must be designed as a self-contained unit with controlled access points. The layout should facilitate a unidirectional flow of personnel and materials, minimizing the risk of cross-contamination. Additionally, the design must incorporate multiple layers of containment, including physical barriers, airflow management systems, and decontamination zones.

One of the most critical aspects of BSL-3 lab layout is the concept of "nested" containment. This means that as you move deeper into the laboratory, each successive area has a higher level of containment. For example, the outermost layer might be a general laboratory space, followed by an anteroom, and finally the BSL-3 work area itself.

The layout of a BSL-3 laboratory must be based on a risk assessment that considers the specific pathogens to be handled, the types of procedures to be performed, and the potential for aerosol generation. This assessment informs every aspect of the design, from the selection of construction materials to the placement of biosafety cabinets.

To illustrate the key components of a BSL-3 lab layout, consider the following table:

| Zone | Purpose | Key Features |

|---|---|---|

| Entry/Exit | Controlled access | Interlocking doors, card readers |

| Anteroom | Donning/doffing PPE | Hand washing sink, storage for PPE |

| Main Laboratory | Primary work area | Biosafety cabinets, work benches |

| Decontamination | Equipment cleaning | Autoclave, chemical showers |

| Mechanical Room | Support systems | HVAC, filtration units |

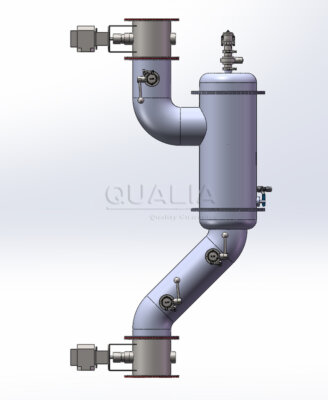

By adhering to these fundamental principles and incorporating these essential zones, QUALIA ensures that BSL-3 laboratories are designed to maintain the highest standards of safety and efficiency.

How does airflow management impact BSL-3 lab design?

Airflow management is a cornerstone of BSL-3 laboratory design, playing a crucial role in maintaining containment and preventing the spread of potentially hazardous agents. The layout of a BSL-3 lab must be intricately planned to support a complex air handling system that creates negative air pressure and ensures proper directional airflow.

The primary goal of airflow management in a BSL-3 lab is to create a pressure gradient that moves air from "clean" areas to potentially contaminated areas. This is achieved through a carefully designed HVAC system that maintains negative air pressure within the containment zone relative to the surrounding areas.

In practice, this means that air should flow from the corridor into the anteroom, and from the anteroom into the main laboratory space. Within the lab itself, air should be directed towards the most potentially hazardous areas, such as biosafety cabinets or other containment devices.

BSL-3 laboratories require a minimum of 6 to 12 air changes per hour, with all exhaust air being HEPA filtered before being discharged outside the building. The airflow system must be designed to prevent air from the containment area from being recirculated to other parts of the facility.

To better understand the impact of airflow on BSL-3 lab design, consider the following table:

| Area | Air Pressure | Direction of Airflow |

|---|---|---|

| Corridor | Positive | Towards anteroom |

| Anteroom | Negative (relative to corridor) | Towards main lab |

| Main Lab | Most negative | Towards containment devices |

| Exhaust | N/A | HEPA filtered to outside |

The layout of the laboratory must accommodate these airflow requirements, influencing the placement of doors, windows, and equipment. For example, biosafety cabinets should be positioned away from doors and high-traffic areas to minimize disruption to airflow patterns.

What are the key considerations for personnel and material flow?

Designing an effective flow for personnel and materials is essential in a BSL-3 laboratory to maintain containment, reduce the risk of contamination, and ensure efficient operations. The layout must facilitate a logical progression from lower to higher containment areas, with clear delineation between clean and potentially contaminated zones.

The entry and exit points of a BSL-3 lab are critical components of the design. Typically, personnel enter through an anteroom where they don appropriate personal protective equipment (PPE) before entering the main laboratory space. Upon exit, they must follow a specific protocol for removing PPE and decontamination.

Material flow is equally important and must be carefully considered in the lab layout. Separate routes for clean and potentially contaminated materials should be established, with designated areas for decontamination of equipment and samples leaving the containment zone.

The design of a BSL-3 laboratory should incorporate a "one-way" flow system where possible, minimizing the need for personnel and materials to backtrack through areas of different containment levels. This unidirectional flow helps maintain the integrity of containment zones and reduces the risk of cross-contamination.

To illustrate the concept of personnel and material flow in a BSL-3 lab, consider this simplified table:

| Stage | Personnel Flow | Material Flow |

|---|---|---|

| Entry | Anteroom → PPE donning → Main lab | Pass-through chamber for supplies |

| Work | Within main lab and containment devices | Stored in designated areas |

| Exit | Main lab → PPE doffing → Decontamination | Through decontamination zone |

The BSL-3 lab layout requirements must account for these movement patterns, ensuring that the physical layout supports safe and efficient operations.

How do equipment placement and workspace design affect BSL-3 lab safety?

The strategic placement of equipment and thoughtful design of workspaces are crucial elements in maintaining safety within a BSL-3 laboratory. The layout must balance the need for efficient workflow with the paramount importance of containment and personnel protection.

Biosafety cabinets (BSCs) are central to BSL-3 lab operations and their placement requires careful consideration. They should be located away from doors, air supply vents, and high-traffic areas to minimize airflow disruptions. Adequate clearance around BSCs is necessary for maintenance and to allow proper function of the cabinet's airflow system.

Workbenches and other laboratory furniture must be designed for easy cleaning and decontamination. The layout should provide sufficient space for safe movement and operation of equipment while minimizing the potential for accidents or spills.

In BSL-3 laboratories, all seams, floors, walls, and ceiling penetrations must be sealed to facilitate fumigation and prevent pest intrusion. Equipment should be selected and placed to allow for easy access to these sealed surfaces for regular inspection and maintenance.

Consider the following table outlining key equipment and workspace considerations:

| Item | Placement Considerations | Safety Features |

|---|---|---|

| Biosafety Cabinets | Away from doors and vents | HEPA filtration, airflow alarms |

| Autoclaves | Near exit, with bioseal | Double-door pass-through design |

| Workbenches | Adequate spacing, cleanable surfaces | Chemical-resistant, seamless construction |

| Storage Units | Secured, with proper ventilation | Lockable, compatible with decontamination procedures |

By carefully considering equipment placement and workspace design, BSL-3 laboratories can enhance safety while maintaining operational efficiency.

What role do decontamination and waste management play in BSL-3 lab layout?

Decontamination and waste management are critical components of BSL-3 laboratory operations, and their requirements significantly influence the layout design. Proper facilities for decontamination and waste handling must be integrated into the lab layout to ensure safe and efficient processing of potentially contaminated materials.

A key feature of BSL-3 labs is the presence of a double-door autoclave, typically located at the laboratory perimeter. This allows for the sterilization of materials before they leave the containment area. The layout must accommodate the autoclave's size and provide appropriate access from both the containment and non-containment sides.

Waste management areas should be clearly defined within the laboratory space. This includes designated areas for the temporary storage of biohazardous waste, as well as facilities for chemical waste handling. The layout should allow for the safe movement of waste from the point of generation to the point of treatment or removal from the facility.

BSL-3 laboratory design must include provisions for the decontamination of large equipment that cannot be autoclaved. This may involve the use of airlocks with decontamination showers or fumigation chambers, which need to be strategically placed within the facility layout.

To better understand the decontamination and waste management considerations in BSL-3 lab layout, refer to this table:

| Process | Location | Key Features |

|---|---|---|

| Autoclaving | Laboratory perimeter | Double-door, bioseal, effluent decontamination |

| Chemical Decontamination | Dedicated area within lab | Chemical-resistant surfaces, proper ventilation |

| Waste Storage | Designated area away from work zones | Secure, properly labeled containers |

| Equipment Decontamination | Airlock or fumigation chamber | Sealable, with appropriate gas/vapor handling |

Incorporating these elements into the BSL-3 lab layout ensures that all materials and equipment can be safely decontaminated before leaving the containment area, maintaining the integrity of the biosafety measures.

How do regulatory requirements shape BSL-3 lab design?

Regulatory requirements play a pivotal role in shaping the design and layout of BSL-3 laboratories. These facilities must comply with a complex set of national and international standards, guidelines, and regulations to ensure the safety of personnel, the community, and the environment.

Key regulatory bodies and standards that influence BSL-3 lab design include the Centers for Disease Control and Prevention (CDC), the National Institutes of Health (NIH), and the World Health Organization (WHO). These organizations provide detailed guidelines on laboratory design, safety equipment, and operational procedures.

One of the most important documents guiding BSL-3 lab design is the CDC's Biosafety in Microbiological and Biomedical Laboratories (BMBL) manual. This comprehensive resource outlines the essential elements required for different biosafety levels, including specific recommendations for BSL-3 facilities.

Compliance with regulatory requirements is not just about meeting minimum standards; it's about creating a culture of safety that is embedded in the very design of the laboratory. BSL-3 lab layouts must be flexible enough to adapt to evolving regulations while maintaining the highest levels of containment and safety.

The following table summarizes some key regulatory considerations for BSL-3 lab design:

| Regulatory Aspect | Requirement | Impact on Layout |

|---|---|---|

| Access Control | Restricted entry, controlled by keycards or biometrics | Secure entry points, anteroom design |

| Airflow Management | Directional airflow, HEPA filtration | HVAC system design, room pressurization |

| Decontamination | Facilities for equipment and waste treatment | Autoclave placement, decon shower location |

| Emergency Systems | Eyewash stations, safety showers, backup power | Strategic placement throughout the lab |

By adhering to these regulatory requirements, BSL-3 laboratories ensure that their design and layout meet the highest standards of safety and compliance.

What are the emerging trends in BSL-3 lab design and layout?

As biological research advances and new technologies emerge, the design and layout of BSL-3 laboratories continue to evolve. These trends reflect not only improvements in safety and efficiency but also changes in research methodologies and the types of pathogens being studied.

One significant trend is the move towards more flexible and modular laboratory designs. This approach allows for easier reconfiguration of lab spaces to accommodate changing research needs or updates in safety protocols. Modular BSL-3 labs can be quickly deployed or modified, providing a more adaptable solution for research institutions and government agencies.

Another emerging trend is the integration of advanced automation and robotics into BSL-3 lab layouts. These technologies can reduce the need for human intervention in high-risk procedures, potentially decreasing the risk of exposure to hazardous agents. The lab layout must be designed to accommodate these automated systems while still maintaining proper containment and workflow.

The future of BSL-3 lab design is likely to see increased integration of digital technologies for real-time monitoring of laboratory conditions, personnel movements, and equipment status. This 'smart lab' approach will require careful consideration of sensor placement and data management systems within the physical layout of the facility.

Consider the following table highlighting some emerging trends in BSL-3 lab design:

| Trend | Description | Impact on Layout |

|---|---|---|

| Modular Design | Prefabricated, easily modifiable lab units | Flexible floor plans, standardized components |

| Automation | Robotic systems for handling hazardous materials | Dedicated spaces for automated equipment |

| Smart Monitoring | IoT sensors for real-time environmental tracking | Integrated network infrastructure |

| Sustainable Design | Energy-efficient systems, reduced environmental impact | Incorporation of green technologies |

These emerging trends are shaping the future of BSL-3 laboratory design, creating more efficient, safe, and adaptable spaces for critical biological research.

Conclusion

The design and layout of BSL-3 laboratories are critical factors in ensuring the safety of personnel, the community, and the environment when working with potentially hazardous biological agents. From fundamental principles of containment to emerging trends in laboratory design, every aspect of a BSL-3 facility's layout must be carefully considered and meticulously implemented.

Key considerations such as airflow management, personnel and material flow, equipment placement, and decontamination procedures all play vital roles in creating a safe and efficient laboratory environment. Regulatory compliance serves as the foundation for these design elements, ensuring that BSL-3 labs meet the highest standards of safety and operational efficiency.

As research needs evolve and new technologies emerge, BSL-3 lab designs are adapting to become more flexible, sustainable, and technologically integrated. These advancements promise to enhance both safety and research capabilities, paving the way for groundbreaking discoveries while maintaining the utmost levels of biosecurity.

The complexity of BSL-3 lab design underscores the importance of collaboration between laboratory managers, researchers, architects, and biosafety professionals. By working together and adhering to stringent safety protocols, we can create laboratory environments that enable crucial research while protecting the health and safety of all involved.

In conclusion, the layout requirements for BSL-3 laboratories are not just about meeting regulatory standards; they are about creating spaces that embody a culture of safety, efficiency, and scientific excellence. As we continue to face global health challenges, well-designed BSL-3 facilities will play an increasingly important role in advancing our understanding of infectious diseases and developing strategies to combat them.

External Resources

University of California – BSL-3 Laboratory Design Standards – This document outlines the mandatory minimum design criteria for Biosafety Level 3 laboratories within the University of California system.

WHO Laboratory Biosafety Manual – The World Health Organization's comprehensive guide on laboratory biosafety, including specific recommendations for BSL-3 facilities.

CDC Biosafety in Microbiological and Biomedical Laboratories (BMBL) – The definitive guide on biosafety practices and principles for laboratories in the United States, including detailed information on BSL-3 design requirements.

NIH Design Requirements Manual (DRM) – The National Institutes of Health's manual for biomedical laboratory and animal research facilities, which includes specifications relevant to BSL-3 labs.

American Biological Safety Association (ABSA) Resources – ABSA provides a wealth of resources on biosafety, including guidelines and best practices for BSL-3 laboratory design and operation.

Kewaunee Scientific – Lab Design for BSL-3 Facilities – This article discusses key considerations for designing BSL-3 labs, focusing on safety and security aspects.

- Journal of the American Biological Safety Association – BSL-3 Laboratory Design – A scientific article providing in-depth analysis of BSL-3 laboratory design considerations and best practices.

Related Contents:

- BSL-3 Lab Layout: Optimizing Space for Safety

- Installing Modular BSL-3 Labs: Expert Guide

- BSL-3 Lab Ventilation: Design for Optimal Safety

- Biosafety Laboratories: BSL-3 vs BSL-4 Distinctions

- BSL-3+ Labs: Enhanced Features for Biosafety

- BSL-4 Air Handling: Critical System Requirements

- BSL-3 vs BSL-4: Key Differences in Lab Safety Levels

- Air Handling in BSL-3 vs BSL-4: System Comparison

- Biosafety Barriers: The Hallmarks of BSL-3 and BSL-4 Labs