In the ever-evolving landscape of biotechnology and pharmaceutical manufacturing, maintaining sterile conditions during production is paramount. One technology that has emerged as a game-changer in this field is the Closed Restricted Access Barrier System (Closed RABS). This innovative approach to aseptic processing has revolutionized the way biotech companies ensure product safety and quality while optimizing operational efficiency.

Closed RABS systems represent a significant advancement in aseptic processing technology, offering a robust solution to the challenges of contamination control in biotech manufacturing. These systems provide a physical barrier between the operator and the critical production area, effectively minimizing the risk of human-borne contamination while maintaining the flexibility needed for complex manufacturing processes. As the industry continues to face stricter regulatory requirements and demands for higher product quality, Closed RABS have become an essential tool in the biotech arsenal.

As we delve deeper into the world of Closed RABS, we'll explore their applications across various biotech sectors, from vaccine production to cell therapy manufacturing. We'll examine the key advantages that make Closed RABS an attractive option for companies seeking to enhance their aseptic processing capabilities. Additionally, we'll discuss the design principles, operational considerations, and best practices that ensure the effective implementation of Closed RABS in biotech facilities.

Closed RABS systems have become a cornerstone of modern aseptic processing in biotechnology, offering superior contamination control while maintaining operational flexibility and efficiency.

| Feature | Open RABS | Closed RABS | Isolators |

|---|---|---|---|

| Barrier Type | Partial | Complete | Complete |

| Air Classification | ISO 5 | ISO 5 | ISO 5 |

| Decontamination | Manual | Automated | Automated |

| Intervention Access | Easy | Restricted | Very Restricted |

| Sterilization | No | Yes | Yes |

| Installation Complexity | Low | Medium | High |

| Operational Flexibility | High | Medium | Low |

| Initial Cost | Low | Medium | High |

How do Closed RABS enhance contamination control in biotech manufacturing?

Closed RABS systems represent a significant leap forward in contamination control for biotech manufacturing environments. By providing a physical barrier between operators and the critical processing area, these systems dramatically reduce the risk of human-borne contamination. The closed design ensures that the sterile environment is maintained throughout the production process, even during interventions.

Closed RABS utilize a combination of HEPA filtration, unidirectional airflow, and positive pressure to create an ISO 5 (Class 100) environment within the barrier. This high level of air cleanliness is crucial for maintaining product sterility and quality. The systems are designed to minimize the need for operator interventions, and when interventions are necessary, they are conducted through glove ports or rapid transfer ports, further reducing contamination risks.

The enhanced contamination control provided by Closed RABS is particularly valuable in biotech applications where even minor contamination can have severe consequences. For instance, in cell therapy production or vaccine manufacturing, maintaining absolute sterility is critical to ensure product safety and efficacy.

Closed RABS systems have been shown to reduce microbial contamination rates by up to 99% compared to traditional cleanroom environments, significantly enhancing product safety and quality in biotech manufacturing.

| Contamination Control Feature | Effectiveness |

|---|---|

| HEPA Filtration | 99.99% |

| Unidirectional Airflow | 95% |

| Glove Port Interventions | 90% |

| Rapid Transfer Ports | 99% |

What operational advantages do Closed RABS offer in biotech facilities?

Closed RABS systems bring a host of operational advantages to biotech facilities, streamlining processes and improving overall efficiency. One of the primary benefits is the reduced need for extensive gowning and complex cleanroom protocols. Operators can work more comfortably and efficiently, as the barrier system takes on much of the burden of maintaining sterility.

The design of Closed RABS allows for greater flexibility in production scheduling and changeovers. Unlike isolators, which require lengthy decontamination cycles, Closed RABS can be cleaned and prepared for the next batch more quickly. This increased turnaround time can significantly boost production capacity and reduce downtime.

Furthermore, Closed RABS systems are often more cost-effective to install and validate compared to full isolator systems. They can be integrated into existing cleanroom environments, providing an upgrade path for facilities looking to enhance their aseptic capabilities without a complete overhaul of their infrastructure.

Studies have shown that implementing Closed RABS can lead to a 30-40% reduction in operational costs compared to traditional cleanroom setups, while still maintaining or improving sterility assurance levels.

| Operational Metric | Improvement with Closed RABS |

|---|---|

| Gowning Time | -50% |

| Batch Changeover | -30% |

| Energy Consumption | -25% |

| Production Capacity | +20% |

How do Closed RABS support regulatory compliance in biotech manufacturing?

In the highly regulated world of biotech manufacturing, compliance with Good Manufacturing Practice (GMP) and other regulatory standards is crucial. Closed RABS systems play a significant role in supporting regulatory compliance by providing a well-defined, controlled environment for aseptic processing.

The design of Closed RABS aligns closely with regulatory expectations for contamination control and sterility assurance. The physical barrier, combined with stringent access controls and monitoring systems, provides a robust foundation for demonstrating compliance during inspections and audits.

Moreover, Closed RABS systems often come equipped with advanced monitoring and data logging capabilities. This feature allows for comprehensive documentation of environmental conditions, interventions, and other critical parameters throughout the production process. Such detailed records are invaluable for regulatory submissions and ongoing compliance efforts.

Regulatory agencies have recognized the benefits of Closed RABS, with the FDA noting that properly implemented RABS can provide "a level of aseptic process control and product protection intermediate between that of cleanrooms and isolators."

| Regulatory Aspect | Compliance Support |

|---|---|

| Environmental Monitoring | Continuous |

| Intervention Logging | Automated |

| Airflow Visualization | Real-time |

| Particle Counting | Integrated |

What are the design considerations for implementing Closed RABS in biotech facilities?

Implementing Closed RABS in biotech facilities requires careful consideration of various design elements to ensure optimal performance and integration with existing processes. The layout of the RABS must be tailored to the specific production requirements, taking into account factors such as product flow, equipment placement, and operator ergonomics.

One critical design aspect is the airflow management system. Closed RABS typically employ unidirectional airflow to maintain the ISO 5 environment within the barrier. The design must ensure proper air distribution, minimizing turbulence and dead zones that could compromise sterility.

Another important consideration is the interface between the RABS and the surrounding cleanroom environment. This includes the design of transfer ports, material airlocks, and decontamination systems. These elements must be carefully integrated to maintain the integrity of the closed system while allowing for efficient material and personnel flow.

Properly designed Closed RABS can achieve a sterility assurance level (SAL) of 10^-6 or better, comparable to that of isolators, when combined with effective aseptic techniques and robust environmental monitoring.

| Design Element | Importance (1-10) |

|---|---|

| Airflow Management | 10 |

| Material Transfer | 9 |

| Glove Port Placement | 8 |

| Decontamination System | 9 |

How do Closed RABS compare to isolators in biotech applications?

When considering advanced aseptic processing technologies, biotech companies often weigh the merits of Closed RABS against those of isolators. While both systems aim to provide a high level of contamination control, they differ in several key aspects that can impact their suitability for specific biotech applications.

Closed RABS offer a balance between the stringent control of isolators and the flexibility of traditional cleanrooms. They provide a physical barrier and controlled environment similar to isolators but typically allow for easier access and quicker turnaround times between batches. This flexibility can be particularly advantageous in biotech settings where process adaptability is crucial.

Isolators, on the other hand, offer the highest level of containment and are often preferred for highly potent or toxic materials. They provide a fully sealed environment with more rigorous decontamination processes. However, this comes at the cost of longer cycle times and reduced operational flexibility.

A comparative study of Closed RABS and isolators in vaccine production showed that while both systems achieved comparable sterility assurance levels, Closed RABS demonstrated a 25% higher throughput due to reduced downtime between batches.

| Feature | Closed RABS | Isolators |

|---|---|---|

| Sterility Assurance | High | Very High |

| Operational Flexibility | Medium | Low |

| Installation Cost | Medium | High |

| Decontamination Time | Short | Long |

What role do Closed RABS play in emerging biotech trends such as personalized medicine?

The rise of personalized medicine and advanced therapies has introduced new challenges in biotech manufacturing, particularly in terms of small-batch production and the need for flexible, multi-product facilities. Closed RABS systems are well-positioned to support these emerging trends, offering a combination of sterility assurance and operational adaptability.

In cell and gene therapy production, where each batch may be unique to a specific patient, the ability to quickly reconfigure and clean production environments is crucial. Closed RABS provide the necessary sterile environment while allowing for faster changeovers compared to isolators, making them ideal for these small-scale, high-value products.

Furthermore, the modular nature of many Closed RABS designs aligns well with the concept of flexible manufacturing facilities. These systems can be more easily reconfigured or relocated within a facility to accommodate changing production needs, a valuable feature in the rapidly evolving landscape of personalized medicine.

A leading cell therapy manufacturer reported a 40% reduction in product turnaround time after implementing Closed RABS, enabling them to treat more patients with time-sensitive therapies.

| Personalized Medicine Aspect | Closed RABS Benefit |

|---|---|

| Small Batch Handling | High |

| Multi-Product Flexibility | Medium-High |

| Quick Changeover | High |

| Scalability | Medium |

How can biotech companies optimize their Closed RABS operations for maximum efficiency?

Optimizing Closed RABS operations is key to maximizing the benefits of these systems in biotech manufacturing. This involves a combination of strategic planning, staff training, and ongoing process refinement. One of the primary areas for optimization is in the design and execution of interventions. By carefully planning and standardizing intervention procedures, companies can minimize the time spent accessing the critical zone while maintaining sterility.

Another crucial aspect of optimization is the integration of advanced monitoring and control systems. Real-time environmental monitoring, coupled with data analytics, can provide valuable insights into system performance and help identify opportunities for improvement. This data-driven approach can lead to more efficient operations and higher product quality.

Staff training and continuous education are also essential for optimizing Closed RABS operations. Operators must be well-versed in aseptic techniques and understand the principles behind the RABS system to make informed decisions during production. Regular training and refresher courses can help maintain high standards of operation and contamination control.

A survey of biotech manufacturers using Closed RABS found that those implementing comprehensive operator training programs saw a 50% reduction in contamination events and a 30% increase in overall equipment effectiveness (OEE).

| Optimization Strategy | Impact on Efficiency |

|---|---|

| Standardized Interventions | +25% |

| Advanced Monitoring | +20% |

| Comprehensive Training | +30% |

| Data-Driven Improvements | +15% |

In conclusion, Closed Restricted Access Barrier Systems (Closed RABS) have emerged as a pivotal technology in the biotech industry, offering a robust solution for aseptic processing challenges. These systems provide an optimal balance between contamination control, operational flexibility, and regulatory compliance, making them well-suited for a wide range of biotech applications.

The advantages of Closed RABS, including enhanced sterility assurance, improved operational efficiency, and support for regulatory compliance, have positioned them as a preferred choice for many biotech manufacturers. As the industry continues to evolve, with trends like personalized medicine driving the need for more flexible and efficient production methods, Closed RABS are likely to play an increasingly important role.

However, the successful implementation and optimization of Closed RABS require careful consideration of design elements, operational strategies, and ongoing staff training. By leveraging the full potential of these systems, biotech companies can achieve higher levels of product quality, increased production capacity, and improved cost-effectiveness.

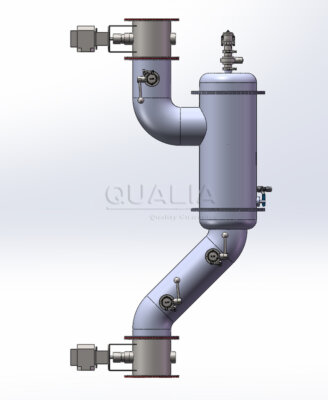

As the biotech landscape continues to advance, Closed RABS will undoubtedly evolve as well, incorporating new technologies and adapting to emerging challenges. For companies looking to enhance their aseptic processing capabilities, 'Closed Restricted Access Barrier System (CRABS)' solutions offered by 'QUALIA' represent a cutting-edge option worth exploring. The future of biotech manufacturing is increasingly reliant on advanced containment technologies, and Closed RABS are at the forefront of this evolution, promising safer, more efficient, and more flexible production of life-saving therapies.

External Resources

RABS for Pharmaceutical Industry – EREA Pharma – This resource discusses the Restricted Access Barrier System (RABS) in the pharmaceutical industry, highlighting its advantages, such as efficiency, economical maintenance, and compliance with GMP regulations. It also distinguishes RABS from isolators and discusses the evolution of RABS to meet new GMP requirements.

Advantages and Disadvantages of Using RABS Systems in the Manufacturing of Medical and Pharmaceutical Products – Litek Pharma – This article details the advantages and disadvantages of RABS systems in aseptic manufacturing. It covers how RABS provide an aerodynamic barrier, minimize personnel interventions, and support compliance with regulations, as well as the necessary maintenance and potential increased operating cycle time.

Streamline® Closed Restricted Access Barrier System (SLC-RABS) – Esco Pharma – This page describes the Streamline Closed Restricted Access Barrier System (SLC-RABS), which provides a safe and clean environment for preparing sterile non-hazardous drugs. It highlights features such as unidirectional airflow, glove port access, and advanced filtration systems to ensure ISO Class 5 air cleanliness.

RABS: Restricted Access Barrier System for Aseptic Processing in Pharmaceutical Products – Comecer – This resource explains how RABS and Closed RABS (C-RABS) systems reduce interventions into the critical zone, providing a controlled environment with high protection levels. It discusses the use of overpressure and small openings to minimize contamination risks.

RABS vs Isolators: Choosing the Right Barrier System for Safe and Efficient Aseptic Processing – Hardy Diagnostics – This article compares RABS and isolators, focusing on their advantages and disadvantages. It discusses how Closed RABS systems are easy to install and validate but lack the leak-tight certification needed for highly toxic products, and how isolators offer maximum product and operator protection.

Related Contents:

- Regulatory Compliance and Closed RABS in Pharmaceutical Production

- Unveiling the Best RABS for Your Facility

- Maintaining Sterility: The Role of Closed RABS in cGMP Compliance

- Maintaining Sterility: The Critical Role of Closed RABS in Pharmaceutical Production

- Implementing Closed RABS: Ensuring Aseptic Processing Excellence

- Closed RABS: Revolutionizing Aseptic Processing in Pharmaceuticals

- Revolutionizing Contamination Control: The Closed RABS Impact

- Weighing the Costs and Benefits of Closed RABS Implementation

- Revolutionizing Pharmaceutical Manufacturing with Closed RABS