The landscape of sterility testing is undergoing a significant transformation, driven by technological advancements and the ever-increasing demands of the pharmaceutical and biopharmaceutical industries. As we look towards the future, isolator trends are emerging as a pivotal factor in shaping the next generation of sterility testing methodologies. These innovative systems are revolutionizing how we approach contamination control and product safety, offering unprecedented levels of precision and efficiency.

In this comprehensive exploration of the future of sterility testing, we'll delve into the latest isolator trends that are set to redefine industry standards. From advanced barrier technologies to integrated rapid microbial detection systems, we'll examine how these developments are addressing long-standing challenges and opening new possibilities for manufacturers and regulators alike. As we navigate through the complexities of modern sterility testing, we'll uncover the potential impact on product quality, regulatory compliance, and operational efficiency.

The evolution of isolator technology is not just a matter of incremental improvements; it represents a paradigm shift in how we conceive and implement sterility assurance. As we transition into the main content of this article, we'll explore the multifaceted aspects of this transformation, including the integration of artificial intelligence, the adoption of single-use systems, and the push towards more sustainable practices in sterility testing.

"The future of sterility testing lies in the seamless integration of advanced isolator technologies with rapid and sensitive detection methods, paving the way for a new era of product safety and quality assurance in the pharmaceutical industry."

How Are Next-Generation Isolators Revolutionizing Sterility Testing?

The advent of next-generation isolators is fundamentally changing the landscape of sterility testing. These advanced systems are designed to provide unparalleled control over the testing environment, minimizing the risk of contamination and enhancing the reliability of test results. By incorporating cutting-edge materials and intelligent design features, modern isolators are setting new benchmarks for aseptic processing and sterility assurance.

Next-generation isolators are characterized by their improved barrier technologies, enhanced ergonomics, and integration with automated systems. These features not only improve the accuracy of sterility tests but also streamline workflows, reducing the time and resources required for testing procedures.

The impact of these advancements extends beyond mere technological improvements. They are reshaping operational protocols, influencing regulatory approaches, and driving the development of new sterility testing methodologies. As manufacturers and testing laboratories adopt these state-of-the-art isolators, they're experiencing significant gains in productivity and confidence in their sterility assurance programs.

"Next-generation isolators are not just tools; they are catalysts for a new era of sterility testing, combining unprecedented environmental control with enhanced user interfaces to deliver superior reliability and efficiency."

| Feature | Benefit |

|---|---|

| Advanced barrier technology | Reduced risk of contamination |

| Improved ergonomics | Enhanced operator comfort and efficiency |

| Automation integration | Streamlined workflows and reduced human error |

| Smart monitoring systems | Real-time environmental control and data logging |

In conclusion, next-generation isolators are at the forefront of the future of sterility testing, offering a powerful combination of technological sophistication and practical benefits that are driving the industry towards more reliable, efficient, and cost-effective sterility testing practices.

What Role Does Artificial Intelligence Play in Modern Sterility Testing Isolators?

Artificial Intelligence (AI) is rapidly becoming an integral component of modern sterility testing isolators, ushering in a new era of precision and efficiency. The integration of AI technologies into isolator systems is transforming how we approach contamination detection, environmental monitoring, and data analysis in sterility testing processes.

AI-powered isolators are equipped with advanced sensors and machine learning algorithms that can continuously monitor and analyze environmental conditions within the testing chamber. These systems can detect subtle changes in parameters such as air pressure, particle counts, and temperature fluctuations, providing real-time alerts and predictive maintenance recommendations.

Furthermore, AI is revolutionizing the interpretation of sterility test results. Machine learning models trained on vast datasets can identify patterns and anomalies that might be imperceptible to human observers, potentially flagging contamination events before they become critical issues.

"The integration of AI in sterility testing isolators marks a pivotal shift from reactive to proactive quality assurance, enabling predictive analytics and intelligent decision-making in contamination control."

| AI Application | Impact on Sterility Testing |

|---|---|

| Real-time monitoring | Continuous assessment of critical parameters |

| Predictive maintenance | Reduced downtime and improved reliability |

| Automated result interpretation | Enhanced accuracy and faster turnaround times |

| Pattern recognition | Early detection of contamination trends |

In conclusion, the role of AI in modern sterility testing isolators is multifaceted and transformative. As these intelligent systems become more sophisticated, they promise to enhance the reliability, efficiency, and effectiveness of sterility testing processes, ultimately contributing to higher standards of product safety and quality in the pharmaceutical industry.

How Are Single-Use Technologies Changing the Landscape of Sterility Testing?

Single-use technologies are making significant inroads in the field of sterility testing, offering a range of benefits that are reshaping traditional approaches to contamination control and aseptic processing. These disposable systems are designed to minimize the risk of cross-contamination, reduce cleaning and validation requirements, and increase operational flexibility in sterility testing environments.

The adoption of single-use components in sterility testing isolators is gaining momentum, with manufacturers increasingly recognizing the advantages of disposable glove systems, transfer ports, and even entire isolator liners. These technologies not only simplify decontamination processes but also allow for rapid changeovers between different products or testing protocols.

Moreover, single-use technologies are particularly valuable in multi-product facilities where the risk of cross-contamination is high. By eliminating the need for complex cleaning validation between batches, these systems can significantly reduce downtime and increase throughput in sterility testing operations.

"Single-use technologies in sterility testing isolators are not just a trend; they represent a fundamental shift towards more agile, efficient, and contamination-resistant testing methodologies in pharmaceutical quality control."

| Single-Use Component | Benefit in Sterility Testing |

|---|---|

| Disposable glove systems | Reduced risk of contamination transfer |

| Single-use transfer ports | Simplified material transfer and decontamination |

| Isolator liners | Faster turnaround times between tests |

| Disposable sampling tools | Eliminated need for sterilization between uses |

In conclusion, single-use technologies are proving to be a game-changer in the landscape of sterility testing. As these disposable solutions continue to evolve and improve, they are likely to become an increasingly integral part of sterility testing protocols, offering enhanced contamination control, operational efficiency, and flexibility to meet the diverse needs of modern pharmaceutical manufacturing.

What Advancements in Rapid Microbial Detection Are Shaping Isolator Design?

Advancements in rapid microbial detection technologies are having a profound impact on the design and functionality of sterility testing isolators. These innovative detection methods are enabling faster, more sensitive, and more reliable identification of potential contaminants, driving the evolution of isolator systems to accommodate and leverage these new capabilities.

Modern isolators are being engineered with integrated rapid microbial detection systems that can provide near real-time results. Technologies such as ATP bioluminescence, flow cytometry, and nucleic acid amplification are being incorporated directly into isolator designs, allowing for continuous monitoring and rapid response to potential contamination events.

These advancements are not only improving the speed and accuracy of sterility testing but are also influencing the overall workflow within isolator systems. Isolator designs now often include dedicated spaces for sample preparation and analysis, as well as interfaces for data integration with laboratory information management systems (LIMS).

"The integration of rapid microbial detection technologies into isolator design is catalyzing a shift towards more dynamic, responsive sterility testing processes, where contamination can be detected and addressed in real-time."

| Rapid Detection Method | Impact on Isolator Design |

|---|---|

| ATP bioluminescence | Integrated luminometers for instant contamination checks |

| Flow cytometry | Dedicated fluidics systems within isolators |

| Nucleic acid amplification | On-board PCR capabilities for species-specific detection |

| Spectroscopic methods | Built-in spectrometers for non-destructive testing |

In conclusion, the advancements in rapid microbial detection are driving significant changes in isolator design, pushing towards more integrated, efficient, and responsive sterility testing systems. As these technologies continue to evolve, we can expect to see even more sophisticated isolator designs that further streamline the sterility testing process and enhance contamination control capabilities.

How Is Sustainability Being Incorporated into Future Sterility Testing Isolators?

Sustainability is becoming an increasingly important consideration in the design and operation of sterility testing isolators. As the pharmaceutical industry faces growing pressure to reduce its environmental footprint, manufacturers and testing facilities are exploring innovative ways to make sterility testing more sustainable without compromising on quality or safety.

One of the key trends in sustainable isolator design is the focus on energy efficiency. Next-generation isolators are being equipped with advanced HVAC systems and intelligent power management features that significantly reduce energy consumption. Additionally, the use of LED lighting and low-power electronic components is further contributing to the overall energy efficiency of these systems.

Material selection is another area where sustainability is making an impact. Manufacturers are increasingly opting for recyclable or biodegradable materials in isolator construction, particularly for disposable components. This shift not only reduces waste but also aligns with broader corporate sustainability goals.

"The future of sterility testing isolators lies in striking a balance between rigorous contamination control and environmental responsibility, driving innovations that benefit both product safety and planetary health."

| Sustainable Feature | Environmental Impact |

|---|---|

| Energy-efficient HVAC | Reduced carbon footprint |

| Recyclable materials | Decreased landfill waste |

| Water conservation systems | Lower water consumption |

| Eco-friendly cleaning agents | Reduced chemical pollution |

In conclusion, the incorporation of sustainability into future sterility testing isolators is not just an ethical imperative but also a practical necessity. As regulations around environmental impact tighten and consumers demand more responsible practices, sustainable isolator designs will likely become the norm rather than the exception in the pharmaceutical industry.

What Regulatory Changes Are Influencing the Evolution of Sterility Testing Isolators?

Regulatory bodies around the world are continuously updating their guidelines and requirements for sterility testing, and these changes are having a significant impact on the design and functionality of isolator systems. As regulatory agencies push for more stringent contamination control and greater data integrity, isolator manufacturers are responding with innovations that meet and exceed these evolving standards.

One of the key regulatory trends influencing isolator design is the emphasis on continuous environmental monitoring. Regulatory bodies are increasingly requiring real-time data on critical parameters such as air quality, pressure differentials, and particle counts. As a result, modern isolators are being equipped with sophisticated monitoring systems that can provide continuous data streams and automatic alerts when parameters deviate from acceptable ranges.

Another important regulatory focus is on data integrity and traceability. This has led to the integration of advanced data management systems within isolators, capable of securely capturing, storing, and transmitting test data in compliance with regulatory requirements such as 21 CFR Part 11.

"Regulatory changes are not just challenges to overcome; they are catalysts for innovation in sterility testing isolator design, driving the development of more sophisticated, reliable, and compliant systems."

| Regulatory Focus | Impact on Isolator Design |

|---|---|

| Continuous monitoring | Integration of real-time sensor networks |

| Data integrity | Secure, compliant data management systems |

| Risk-based approaches | Flexible designs to accommodate varying product needs |

| Operator safety | Enhanced ergonomics and containment features |

In conclusion, regulatory changes are playing a crucial role in shaping the future of sterility testing isolators. As regulatory bodies continue to refine their requirements, we can expect to see further innovations in isolator design that not only meet these standards but also push the boundaries of what's possible in sterility assurance.

How Are Ergonomics and Operator Safety Being Improved in Next-Generation Isolators?

Ergonomics and operator safety are becoming increasingly critical considerations in the design of next-generation sterility testing isolators. As the industry recognizes the importance of human factors in maintaining consistent and reliable testing procedures, isolator manufacturers are incorporating advanced ergonomic features and safety measures into their designs.

Modern isolators are being engineered with adjustable work surfaces, optimized glove port positions, and improved lighting systems to reduce operator fatigue and enhance comfort during extended testing sessions. These ergonomic improvements not only boost productivity but also minimize the risk of errors that can occur due to physical strain or discomfort.

In terms of safety, next-generation isolators are incorporating advanced containment technologies to protect operators from exposure to hazardous materials. This includes improved airflow management systems, fail-safe mechanisms for maintaining negative pressure, and enhanced filtration systems that ensure the highest level of air quality within the working environment.

"The focus on ergonomics and operator safety in next-generation isolators is not just about compliance; it's about creating a work environment that promotes accuracy, efficiency, and the well-being of laboratory personnel."

| Ergonomic/Safety Feature | Benefit |

|---|---|

| Adjustable work surfaces | Reduced physical strain |

| Optimized glove port design | Improved dexterity and comfort |

| Advanced lighting systems | Enhanced visibility and reduced eye strain |

| Fail-safe containment mechanisms | Increased operator protection |

In conclusion, the improvements in ergonomics and operator safety are transforming sterility testing isolators into more user-friendly and secure environments. These advancements not only enhance the quality and reliability of sterility testing but also contribute to a safer and more comfortable workplace for laboratory personnel.

What Role Will Automation Play in the Future of Sterility Testing Isolators?

Automation is poised to play a pivotal role in the future of sterility testing isolators, promising to revolutionize workflows, enhance reliability, and reduce human error in testing procedures. As the pharmaceutical industry continues to embrace Industry 4.0 principles, automated systems are becoming increasingly sophisticated and integral to sterility testing processes.

One of the key areas where automation is making significant strides is in sample handling and preparation. Robotic systems are being integrated into isolator designs to automate tasks such as sample transfer, media fill, and even test initiation. These automated systems not only improve consistency and reduce the risk of contamination but also allow for 24/7 operation, significantly increasing throughput.

Moreover, automation is extending to data management and reporting. Advanced software systems are being developed to automatically collect, analyze, and report test results, ensuring data integrity and facilitating rapid decision-making. These systems can also interface with broader quality management systems, creating a seamless flow of information across the entire manufacturing and testing process.

"Automation in sterility testing isolators is not just about replacing manual tasks; it's about creating intelligent, interconnected systems that can adapt to changing conditions and optimize testing processes in real-time."

| Automated Feature | Impact on Sterility Testing |

|---|---|

| Robotic sample handling | Reduced contamination risk and improved consistency |

| Automated data collection | Enhanced data integrity and real-time analysis |

| Intelligent environmental control | Optimized testing conditions and energy efficiency |

| Predictive maintenance | Minimized downtime and improved reliability |

In conclusion, automation is set to be a defining feature of future sterility testing isolators. As these technologies continue to evolve and become more sophisticated, we can expect to see sterility testing processes that are faster, more reliable, and more efficient than ever before, ultimately contributing to higher standards of product safety and quality in the pharmaceutical industry.

As we look towards the future of sterility testing, it's clear that isolator trends are at the forefront of a significant transformation in the pharmaceutical and biopharmaceutical industries. The advancements we've explored – from next-generation isolator designs and AI integration to single-use technologies and rapid microbial detection methods – are collectively reshaping the landscape of contamination control and product safety.

The emphasis on sustainability, regulatory compliance, ergonomics, and automation is driving the development of more sophisticated, efficient, and user-friendly isolator systems. These innovations are not only enhancing the reliability and speed of sterility testing but also addressing long-standing challenges in the industry, such as reducing environmental impact and improving operator safety.

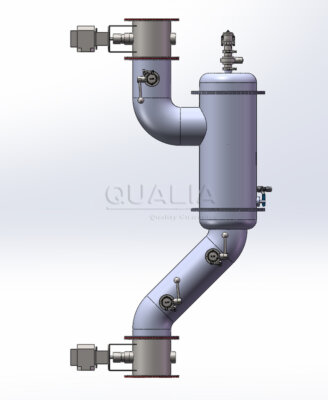

As QUALIA and other industry leaders continue to push the boundaries of what's possible in sterility testing, we can anticipate even more groundbreaking developments on the horizon. The future of sterility testing isolators promises to be one of increased precision, enhanced efficiency, and greater adaptability to the evolving needs of pharmaceutical manufacturing.

In conclusion, the trends we've examined highlight a future where sterility testing is not just a critical quality control measure but an integral part of a more intelligent, sustainable, and effective pharmaceutical production ecosystem. As these technologies continue to evolve and mature, they will undoubtedly play a crucial role in ensuring the safety and efficacy of pharmaceutical products for years to come.

External Resources

Rapid Sterility Testing Market: Technology Advancement Driving Market Growth – This article discusses how technological advancements and an expanding biotechnology industry are expected to boost the growth of the rapid sterility testing market from 2023 to 2032, with a predicted CAGR of 8.20%.

Sterility Testing Market Valuation Set to Worth Over US$ 2.945 Billion By 2032 – This report highlights the significant growth of the sterility testing market, driven by technological advancements, stringent regulatory requirements, and the increasing complexity of drug formulations, especially biologics.

The Benefits of Rapid Sterility Testing – This blog explores the advantages of Rapid Microbiological Methods (RMM) in sterility testing, including faster batch release, operational efficiency, risk reduction, and enhanced data integrity, and discusses the market demand and adoption rates of RMMs.

Sterility Testing Market Report: Size, Share & Forecast | 2032 – This market report provides an outlook on the sterility testing market, forecasting growth driven by increasing biopharmaceutical and pharmaceutical production, strict regulatory mandates, and advancements in sterility testing technologies.

Rapid Sterility Testing: Overcoming Challenges in Cell Therapy – This article discusses recent FDA guidelines emphasizing the need for rapid sterility testing methods, especially in cell therapies with limited shelf lives, and highlights the regulatory landscape and guidelines supporting advanced detection capabilities.

Related Contents:

- Medical Device Testing in Sterility Isolators

- Custom Sterility Test Isolators for Pharma QC

- Sterility Test Isolators for Pharmaceutical Products

- Aseptic Solutions for Sterility Test Isolators

- Sterility Testing: Biosafety Isolator Protocols

- Sterility Testing in OEB4/OEB5 Isolators: Best Methods

- Sterility Test Isolators: Setting Industry Benchmarks

- Controlled Environments in Sterility Test Isolators

- Sterility Testing Ophthalmic Ointments in Isolators