In the ever-evolving landscape of pharmaceutical manufacturing and research, maintaining a safe and controlled environment is paramount. As the industry progresses, so do the standards for containment and safety. Two key players in this arena are OEB4 and OEB5 isolators, each offering unique benefits and features tailored to specific needs. This article delves into the intricacies of these isolators, comparing their capabilities and helping you determine which is the right fit for your facility.

The choice between OEB4 and OEB5 isolators is not just a matter of preference; it's a critical decision that impacts the safety of personnel, the integrity of products, and the overall efficiency of operations. As we explore the nuances of these containment solutions, we'll uncover the key differences in their design, functionality, and applications. From filtration systems to sterilization capabilities, we'll examine the features that set these isolators apart and how they align with various industry requirements.

This comprehensive guide will walk you through the essential aspects of OEB4 and OEB5 isolators, including their containment levels, safety measures, and operational benefits. We'll also discuss the factors you should consider when selecting the appropriate isolator for your specific needs, taking into account the nature of your compounds, regulatory requirements, and facility constraints.

"The selection of an appropriate containment solution is crucial for ensuring the safety of personnel and the integrity of pharmaceutical products. OEB4 and OEB5 isolators represent the pinnacle of containment technology, each offering distinct advantages for different applications."

What are OEB4 and OEB5 Isolators?

Occupational Exposure Bands (OEB) are a critical concept in pharmaceutical manufacturing, categorizing compounds based on their potency and the level of containment required for safe handling. OEB4 and OEB5 isolators are designed to meet the stringent containment requirements for highly potent compounds.

OEB4 isolators are engineered to handle substances with an occupational exposure limit (OEL) ranging from 1-10 µg/m³, while OEB5 isolators are designed for even more potent compounds with an OEL below 1 µg/m³. These isolators provide a physical barrier between the operator and the product, ensuring maximum safety and containment.

Both OEB4 and OEB5 isolators utilize advanced filtration systems, negative pressure environments, and robust construction to maintain the highest levels of containment. However, they differ in their specific design features and capabilities to address the varying potency levels of the compounds they are intended to handle.

"OEB4 and OEB5 isolators represent the cutting edge of containment technology, offering unparalleled protection for operators working with highly potent pharmaceutical compounds."

How Do Filtration Systems Differ Between OEB4 and OEB5 Isolators?

The filtration system is a critical component of any isolator, and the differences between OEB4 and OEB5 isolators in this aspect are significant. OEB4 isolators typically employ a dual HEPA filtration system, providing a high level of containment for most highly potent compounds.

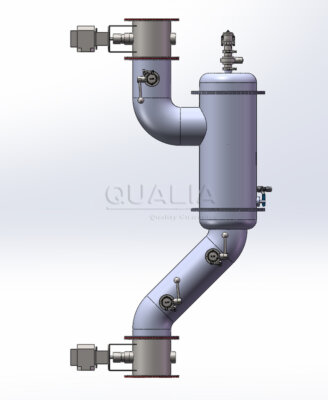

OEB5 isolators, on the other hand, often feature a more advanced triple filtration system, which may include HEPA and ULPA filters. This enhanced filtration ensures even greater protection against the most potent substances. The 'IsoSeries OEB4/OEB5 Isolator' by (QUALIA) exemplifies this advanced filtration technology, offering modular designs that can be tailored to specific containment needs.

In addition to the number of filters, OEB5 isolators may also incorporate safe replaceable bucket filters, allowing for easier maintenance without compromising containment. This feature is particularly important for facilities handling extremely potent compounds, where even minimal exposure can pose significant risks.

"The advanced filtration systems in OEB5 isolators provide an additional layer of safety, making them the preferred choice for facilities working with the most potent pharmaceutical compounds."

| Feature | OEB4 Isolator | OEB5 Isolator |

|---|---|---|

| Filtration System | Dual HEPA | Triple HEPA/ULPA |

| Safe Replaceable Filters | Optional | Standard |

| Filtration Efficiency | 99.995% | 99.9995% |

| Maintenance Complexity | Moderate | High |

What Safety Features Are Unique to OEB5 Isolators?

When it comes to safety, OEB5 isolators take containment to the next level. These isolators are designed with additional features to ensure the utmost protection when handling extremely potent compounds. One notable feature is the independent Air Handling Unit (AHU), which provides precise control over the internal environment.

OEB5 isolators also often incorporate inflatable sealing systems, which create an airtight barrier between the isolator chamber and the external environment. This feature is particularly crucial during material transfer operations, minimizing the risk of containment breaches.

Another safety enhancement found in OEB5 isolators is the implementation of redundant safety systems. These may include backup power supplies, additional alarm systems, and fail-safe mechanisms to maintain containment even in the event of equipment failure or power outages.

"The advanced safety features of OEB5 isolators, such as independent AHUs and inflatable sealing systems, provide an unparalleled level of protection for operators handling the most potent pharmaceutical compounds."

| Safety Feature | OEB4 Isolator | OEB5 Isolator |

|---|---|---|

| Independent AHU | Optional | Standard |

| Inflatable Sealing | Not Common | Standard |

| Redundant Safety Systems | Basic | Advanced |

| Alarm Systems | Standard | Enhanced |

How Do Sterilization Capabilities Compare Between OEB4 and OEB5 Isolators?

Sterilization is a critical aspect of maintaining a contamination-free environment within isolators. Both OEB4 and OEB5 isolators offer sterilization capabilities, but there are notable differences in their approaches and effectiveness.

OEB4 isolators typically provide standard sterilization options, such as manual surface decontamination and the use of hydrogen peroxide vapor (VHP) for periodic deep cleaning. These methods are generally sufficient for maintaining the required level of sterility for OEB4 compounds.

OEB5 isolators, however, often feature more advanced and automated sterilization systems. These may include built-in VHP generators for more frequent and thorough sterilization cycles, as well as integrated UV-C light systems for continuous surface disinfection. Some OEB5 isolators also offer CIP (Clean-in-Place) and SIP (Sterilize-in-Place) capabilities, allowing for more efficient and effective cleaning processes without the need for extensive manual intervention.

"The enhanced sterilization capabilities of OEB5 isolators, including automated VHP systems and integrated UV-C disinfection, ensure a higher level of sterility critical for handling extremely potent compounds."

| Sterilization Feature | OEB4 Isolator | OEB5 Isolator |

|---|---|---|

| Manual Decontamination | Standard | Limited |

| VHP Sterilization | Periodic | Frequent/Automated |

| UV-C Disinfection | Optional | Often Integrated |

| CIP/SIP Capabilities | Rare | More Common |

What Are the Key Differences in Operational Efficiency?

Operational efficiency is a crucial factor when comparing OEB4 and OEB5 isolators. While both types are designed to maintain high levels of containment, there are notable differences in their operational characteristics that can impact productivity and ease of use.

OEB4 isolators generally offer a good balance between containment and operational flexibility. They typically feature ergonomic designs that allow for comfortable operator use over extended periods. The material transfer systems in OEB4 isolators are designed for efficient handling of most highly potent compounds, with airlock or rapid transfer port (RTP) systems that maintain containment during transfers.

OEB5 isolators, designed for the most potent compounds, often prioritize containment over operational speed. They may incorporate more complex material transfer systems, such as double-door transfer chambers or specialized airlocks with additional decontamination steps. While these systems provide enhanced safety, they can potentially increase processing times.

However, advanced OEB5 isolators, like those offered by (QUALIA), are increasingly incorporating features to improve operational efficiency without compromising safety. These may include automated material handling systems, integrated weighing and dispensing equipment, and advanced control systems that optimize workflows.

"While OEB5 isolators prioritize containment for the most potent compounds, advancements in design are bridging the gap in operational efficiency between OEB4 and OEB5 systems, offering both safety and productivity."

| Operational Feature | OEB4 Isolator | OEB5 Isolator |

|---|---|---|

| Material Transfer Speed | Faster | Slower (with exceptions) |

| Ergonomic Design | Good | May be more complex |

| Automation Integration | Moderate | High |

| Workflow Optimization | Standard | Advanced |

How Do Regulatory Requirements Influence the Choice Between OEB4 and OEB5 Isolators?

Regulatory compliance is a critical factor in the pharmaceutical industry, and it plays a significant role in the selection of containment solutions. The choice between OEB4 and OEB5 isolators is often influenced by the specific regulatory requirements applicable to the compounds being handled and the processes being performed.

OEB4 isolators generally meet the regulatory requirements for handling most highly potent compounds. They comply with standards set by organizations such as the FDA, EMA, and ISO for containment and safety in pharmaceutical manufacturing. For many facilities, OEB4 isolators provide sufficient containment to meet regulatory obligations while maintaining operational flexibility.

OEB5 isolators, however, are designed to meet the most stringent regulatory requirements for extremely potent compounds. They often exceed the minimum standards set by regulatory bodies, providing an extra layer of safety and compliance. Facilities handling compounds with very low OELs or those subject to heightened scrutiny may find that OEB5 isolators are necessary to meet their regulatory obligations.

"The selection between OEB4 and OEB5 isolators should be guided not only by the potency of the compounds being handled but also by the specific regulatory requirements applicable to the facility and its processes."

| Regulatory Aspect | OEB4 Isolator | OEB5 Isolator |

|---|---|---|

| Compliance with FDA Standards | Meets | Exceeds |

| EMA Compatibility | Yes | Yes, with additional features |

| ISO Certification | Standard | Advanced |

| Suitability for GMP Processes | Good | Excellent |

What Are the Cost Implications of Choosing Between OEB4 and OEB5 Isolators?

The decision between OEB4 and OEB5 isolators inevitably involves financial considerations. While both types represent significant investments in safety and containment, there are notable differences in their cost structures that facilities must consider.

OEB4 isolators generally have lower initial costs compared to their OEB5 counterparts. This is due to their less complex design and fewer advanced features. The operational costs of OEB4 isolators are also typically lower, with simpler maintenance requirements and lower energy consumption.

OEB5 isolators, with their advanced containment features and more complex systems, come with higher initial costs. The specialized filtration systems, enhanced safety features, and advanced sterilization capabilities contribute to this increased investment. Operational costs for OEB5 isolators can also be higher due to more frequent filter replacements, increased energy consumption, and potentially more complex maintenance procedures.

However, it's important to consider the long-term implications of this investment. For facilities handling extremely potent compounds, the enhanced safety provided by OEB5 isolators can lead to reduced risks of exposure incidents, potentially resulting in long-term cost savings through improved safety records and reduced liability.

"While OEB5 isolators represent a higher initial investment, their advanced containment capabilities can provide long-term value for facilities handling the most potent compounds, potentially offsetting costs through enhanced safety and reduced risk."

| Cost Factor | OEB4 Isolator | OEB5 Isolator |

|---|---|---|

| Initial Investment | Lower | Higher |

| Operational Costs | Moderate | Higher |

| Maintenance Expenses | Lower | Higher |

| Long-term Safety Value | Good | Excellent |

How Do Future-Proofing and Scalability Compare Between OEB4 and OEB5 Isolators?

In the rapidly evolving pharmaceutical industry, the ability to adapt and scale containment solutions is crucial. Both OEB4 and OEB5 isolators offer different approaches to future-proofing and scalability, which can significantly impact a facility's long-term strategy.

OEB4 isolators provide a solid foundation for containment needs, with the flexibility to handle a wide range of highly potent compounds. Many OEB4 systems offer modular designs that allow for some degree of customization and expansion. This adaptability can be beneficial for facilities that anticipate changes in their product portfolio or production volumes.

OEB5 isolators, while more specialized, often incorporate cutting-edge technologies that can provide a longer operational lifespan. Their advanced containment capabilities make them suitable for handling an even broader range of compounds, including those that may be developed in the future with even lower OELs. Some OEB5 isolators, like those offered by (QUALIA), feature highly modular designs that allow for easy reconfiguration and expansion, providing excellent scalability options.

Additionally, OEB5 isolators may offer more advanced integration capabilities with other systems, such as automated material handling or data management platforms. This integration potential can be valuable for facilities looking to implement Industry 4.0 concepts or planning for future technological advancements.

"While both OEB4 and OEB5 isolators offer paths for future growth, OEB5 systems often provide superior long-term adaptability and integration capabilities, making them a strong choice for facilities planning for future expansion and technological advancement."

| Future-Proofing Aspect | OEB4 Isolator | OEB5 Isolator |

|---|---|---|

| Adaptability to New Compounds | Good | Excellent |

| Modularity | Moderate | High |

| Technology Integration | Basic | Advanced |

| Scalability | Good | Excellent |

In conclusion, the choice between OEB4 and OEB5 isolators is a complex decision that requires careful consideration of various factors. Both types of isolators offer high levels of containment and safety, but they differ in their specific capabilities, operational characteristics, and cost implications.

OEB4 isolators provide excellent containment for most highly potent compounds, offering a good balance between safety and operational efficiency. They are generally more cost-effective and can be suitable for a wide range of pharmaceutical manufacturing processes. OEB4 isolators are an excellent choice for facilities handling compounds with OELs between 1-10 µg/m³ and those looking for a flexible containment solution.

OEB5 isolators, on the other hand, represent the pinnacle of containment technology. They offer unparalleled safety features, advanced filtration systems, and superior sterilization capabilities. While they come with higher initial costs and potentially more complex operations, OEB5 isolators provide the highest level of protection for personnel working with the most potent compounds. They are ideal for facilities handling substances with OELs below 1 µg/m³ or those anticipating future needs for enhanced containment.

The decision between OEB4 and OEB5 isolators should be based on a thorough assessment of your facility's specific needs, including the nature of the compounds being handled, regulatory requirements, operational considerations, and long-term strategic plans. It's also worth considering the potential for future expansion and the adaptability of the chosen system to evolving industry standards and technologies.

Ultimately, both OEB4 and OEB5 isolators play crucial roles in ensuring safe and efficient pharmaceutical manufacturing processes. By carefully evaluating your facility's requirements and consulting with experts in containment technology, you can make an informed decision that will support your operations now and in the future. Whether you opt for the balanced approach of OEB4 or the cutting-edge protection of OEB5, investing in high-quality containment solutions is a critical step in safeguarding your personnel, products, and processes in the challenging world of pharmaceutical manufacturing.

External Resources

OEB 4/5 High Containment Sampling Isolator Series – Senieer – This resource provides a detailed comparison of the features and functionalities of OEB4 and OEB5 isolators, including their containment levels, filtration systems, and safety measures.

OEB4 / OEB5 Isolator – BioSafe Tech by QUALIA – This page describes the OEB4 and OEB5 isolators by QUALIA, highlighting their modular design, filtration systems, and sterilization capabilities, which can help in comparing their suitability for different facilities.

OEB5 High Containment Isolator – CPHI Online – This resource outlines the specifications and features of OEB5 high containment isolators, including independent AHU, safe replaceable bucket filters, and inflatable sealing, which can be compared with OEB4 isolators.

OEL / OEB – Esco Pharma – This article explains the Occupational Exposure Bands (OEB) and provides recommendations for containment technologies based on the OEB levels, helping facilities decide between OEB4 and OEB5 isolators.

High Containment Isolators for OEB 4 and OEB 5 Compounds – Pharmaceutical Processing – This article discusses the design and operational features of high containment isolators for OEB 4 and OEB 5 compounds, offering a comparison of their containment efficiencies and safety features.

Containment Solutions for High Potency APIs: OEB 4 vs OEB 5 – PharmTech – This PharmTech article focuses on the containment solutions for high potency APIs, comparing the requirements and technologies for OEB 4 and OEB 5 compounds, which can guide facilities in their selection.

Related Contents:

- Advancing Pharmaceutical Safety: OEB4 and OEB5 Isolators

- The Critical Role of Isolators in HPAPI Handling

- Closed RABS vs. Isolators: Comparing Aseptic Processing Solutions

- Revolutionizing Pharmaceutical Wastewater Treatment

- Navigating the Complexities of High-Potency API Effluent Management

- Regulatory Compliance and Closed RABS in Pharmaceutical Production

- Biosafety Barriers: The Hallmarks of BSL-3 and BSL-4 Labs

- Maintaining Sterility: The Critical Role of Closed RABS in Pharmaceutical Production

- Revolutionizing Pharmaceutical Effluent Treatment: Emerging Technologies