In the ever-evolving landscape of environmental protection and water treatment, ion exchange technology has emerged as a powerful tool in effluent decontamination systems. This innovative approach offers a highly efficient method for removing harmful contaminants from industrial and municipal wastewater, ensuring cleaner and safer water resources for both humans and ecosystems.

Ion exchange technology in effluent decontamination systems utilizes specialized resins to selectively remove dissolved ions from water, replacing them with less harmful ions. This process allows for the effective removal of a wide range of pollutants, including heavy metals, radioactive materials, and organic compounds. The versatility and effectiveness of ion exchange have made it an indispensable component in modern water treatment facilities and industrial applications.

As we delve deeper into the world of ion exchange technology, we'll explore its fundamental principles, various applications in effluent decontamination, and the significant benefits it offers in addressing water pollution challenges. From understanding the different types of ion exchange resins to examining real-world case studies, this article will provide a comprehensive overview of this groundbreaking technology and its role in shaping the future of water treatment.

"Ion exchange technology has revolutionized effluent decontamination systems, offering a highly efficient and cost-effective solution for removing a wide range of contaminants from industrial and municipal wastewater."

Before we dive into the specifics of ion exchange technology in effluent decontamination systems, let's take a look at a comparison of various water treatment methods:

| Treatment Method | Contaminants Removed | Efficiency | Cost | Maintenance Requirements |

|---|---|---|---|---|

| Ion Exchange | Heavy metals, dissolved solids, radioactive materials | High | Medium | Moderate |

| Reverse Osmosis | Dissolved solids, bacteria, viruses | Very High | High | High |

| Activated Carbon | Organic compounds, chlorine, odors | Medium | Low | Low |

| Chemical Precipitation | Heavy metals | Medium | Medium | Moderate |

| Biological Treatment | Organic matter, nutrients | High | Medium | High |

Now, let's explore the various aspects of ion exchange technology in effluent decontamination systems.

How does ion exchange work in effluent treatment?

Ion exchange is a powerful process that forms the backbone of many effluent decontamination systems. At its core, this technology involves the exchange of ions between a solid phase (the resin) and a liquid phase (the contaminated water). The resin, typically in the form of small beads, contains functional groups that can selectively attract and hold onto specific ions present in the effluent.

In effluent treatment, ion exchange works by passing the contaminated water through a bed of ion exchange resin. As the water flows through, the targeted contaminant ions are captured by the resin, while harmless ions are released into the water. This process continues until the resin reaches its capacity and requires regeneration.

"The ion exchange process in effluent treatment can remove up to 99% of dissolved ionic contaminants, making it one of the most effective methods for water purification in industrial and municipal settings."

| Ion Exchange Resin Type | Target Contaminants | Typical Applications |

|---|---|---|

| Cation Exchange Resin | Calcium, Magnesium, Heavy Metals | Water Softening, Metal Recovery |

| Anion Exchange Resin | Nitrates, Sulfates, Chlorides | Demineralization, Dealkalization |

| Chelating Resin | Heavy Metals, Radioactive Elements | Nuclear Waste Treatment, Industrial Effluents |

What types of contaminants can ion exchange remove from effluents?

Ion exchange technology is remarkably versatile in its ability to remove a wide range of contaminants from effluents. This versatility stems from the various types of ion exchange resins available, each designed to target specific groups of contaminants. The technology is particularly effective in removing dissolved ionic species, making it an ideal choice for many industrial and municipal wastewater treatment applications.

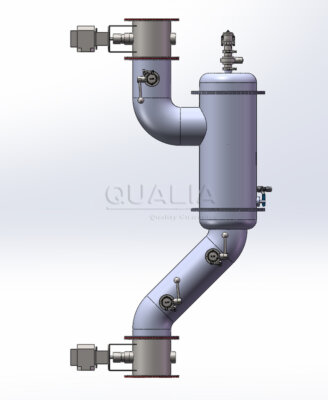

Some of the key contaminants that ion exchange can effectively remove include heavy metals (such as lead, copper, and zinc), radioactive materials, nitrates, sulfates, and even certain organic compounds. The 'Effluent Decontamination System (EDS) for BSL-2, 3 and 4 Liquid Waste' by QUALIA is an excellent example of how ion exchange technology can be applied to treat highly contaminated effluents from biosafety laboratories.

"Ion exchange systems can effectively remove up to 95% of heavy metals from industrial effluents, significantly reducing the environmental impact of manufacturing processes and helping companies meet stringent discharge regulations."

| Contaminant | Removal Efficiency | Typical Ion Exchange Resin Used |

|---|---|---|

| Lead | 99% | Strong Acid Cation |

| Copper | 98% | Chelating Resin |

| Nitrates | 90% | Strong Base Anion |

| Radioactive Cesium | 99.9% | Zeolite |

| Chromium (VI) | 95% | Strong Base Anion |

What are the advantages of using ion exchange in effluent decontamination?

Ion exchange technology offers numerous advantages in effluent decontamination systems, making it a preferred choice for many industries and municipalities. One of the primary benefits is its high efficiency in removing a wide range of contaminants, even at low concentrations. This capability allows for the treatment of complex effluents that may contain multiple types of pollutants.

Another significant advantage is the technology's ability to operate continuously with minimal downtime. Ion exchange systems can be designed for automatic regeneration, ensuring a constant supply of treated water. Additionally, these systems are often more compact than alternative treatment methods, making them suitable for facilities with limited space.

"Ion exchange systems in effluent decontamination can reduce operational costs by up to 30% compared to traditional chemical treatment methods, while also minimizing the use of hazardous chemicals in the treatment process."

| Advantage | Description | Impact |

|---|---|---|

| High Selectivity | Can target specific contaminants | Improved treatment efficiency |

| Low Energy Consumption | Operates at ambient temperature and pressure | Reduced operational costs |

| Minimal Chemical Usage | Relies on physical-chemical process | Environmentally friendly |

| Water Recovery | High recovery rates possible | Conservation of water resources |

| Flexibility | Can be easily combined with other treatment methods | Enhanced overall treatment effectiveness |

How does ion exchange compare to other effluent treatment technologies?

When evaluating effluent treatment technologies, it's crucial to consider various factors such as efficiency, cost-effectiveness, and environmental impact. Ion exchange technology stands out in many of these aspects when compared to other common treatment methods like reverse osmosis, chemical precipitation, or activated carbon adsorption.

One of the key advantages of ion exchange is its ability to selectively remove specific contaminants without affecting the overall composition of the water. This selectivity can be particularly beneficial in industrial applications where certain minerals or elements need to be retained in the treated water. Additionally, ion exchange systems typically have lower energy requirements compared to pressure-driven processes like reverse osmosis, resulting in reduced operational costs.

"Studies have shown that ion exchange systems can achieve up to 40% lower operational costs compared to reverse osmosis systems when treating industrial effluents with high dissolved solids content."

| Treatment Technology | Energy Consumption | Water Recovery Rate | Contaminant Selectivity | Initial Investment |

|---|---|---|---|---|

| Ion Exchange | Low | 95-98% | High | Medium |

| Reverse Osmosis | High | 75-85% | Low | High |

| Chemical Precipitation | Medium | 90-95% | Medium | Low |

| Activated Carbon | Low | 95-98% | Medium | Low |

What are the design considerations for ion exchange systems in effluent treatment?

Designing an effective ion exchange system for effluent treatment requires careful consideration of various factors to ensure optimal performance and efficiency. The first step in the design process is a thorough analysis of the effluent composition, including the types and concentrations of contaminants present. This information is crucial for selecting the appropriate ion exchange resin and determining the system capacity.

Other important design considerations include the flow rate of the effluent, the desired level of treatment, and any specific regulatory requirements that must be met. The system must also be designed to handle variations in effluent composition and flow, which are common in industrial applications.

"Proper design of ion exchange systems can increase treatment efficiency by up to 25% and extend resin life by up to 40%, resulting in significant long-term cost savings for effluent treatment facilities."

| Design Parameter | Importance | Impact on Performance |

|---|---|---|

| Resin Selection | High | Determines contaminant removal efficiency |

| Bed Depth | Medium | Affects contact time and treatment capacity |

| Flow Rate | High | Influences treatment efficiency and system size |

| Regeneration Method | Medium | Affects operational costs and downtime |

| Pre-treatment | Medium | Protects resin from fouling and extends life |

How is ion exchange technology integrated into comprehensive effluent decontamination systems?

Ion exchange technology is often a key component of comprehensive effluent decontamination systems, working in synergy with other treatment methods to achieve optimal results. In many cases, ion exchange units are integrated as a polishing step after primary and secondary treatment processes, removing residual contaminants and ensuring that the treated effluent meets stringent quality standards.

The integration of ion exchange technology can significantly enhance the overall performance of effluent decontamination systems. For example, it can be used in conjunction with biological treatment to remove nutrients like nitrates and phosphates, or with membrane systems to reduce the load on reverse osmosis units and extend their operational life.

"Integrated effluent decontamination systems that incorporate ion exchange technology have been shown to achieve up to 99.9% removal of target contaminants, meeting even the most stringent regulatory requirements for water discharge and reuse."

| Treatment Stage | Technology | Role of Ion Exchange |

|---|---|---|

| Pre-treatment | Screening, Sedimentation | N/A |

| Primary Treatment | Chemical Precipitation | Polishing for metal removal |

| Secondary Treatment | Biological Processes | Nutrient removal |

| Tertiary Treatment | Membrane Filtration | Pre-treatment to protect membranes |

| Final Polishing | Ion Exchange | Removal of residual contaminants |

What are the challenges and limitations of using ion exchange in effluent decontamination?

While ion exchange technology offers numerous benefits in effluent decontamination, it's important to acknowledge its challenges and limitations. One of the primary challenges is the need for regular regeneration of the ion exchange resins. This process involves using chemicals to restore the resin's exchange capacity, which can generate a secondary waste stream that requires proper management.

Another limitation is the technology's sensitivity to certain contaminants, such as organic matter or suspended solids, which can foul the resin and reduce its effectiveness. This often necessitates pre-treatment steps to protect the ion exchange system. Additionally, the selectivity of ion exchange resins, while generally an advantage, can sometimes be a limitation when dealing with complex effluents containing multiple contaminants with similar properties.

"Despite its challenges, advancements in resin technology have improved the regeneration efficiency of ion exchange systems by up to 30% in recent years, significantly reducing the volume of secondary waste generated during the process."

| Challenge | Impact | Mitigation Strategy |

|---|---|---|

| Resin Fouling | Reduced efficiency | Implement effective pre-treatment |

| Regeneration Waste | Secondary pollution | Optimize regeneration process, waste treatment |

| Limited Capacity | Frequent regeneration | Proper sizing, use of high-capacity resins |

| Selectivity Issues | Incomplete treatment | Combine with other treatment methods |

| High Initial Cost | ROI concerns | Focus on long-term benefits, operational savings |

What does the future hold for ion exchange technology in effluent decontamination?

The future of ion exchange technology in effluent decontamination looks promising, with ongoing research and development aimed at addressing current limitations and expanding its applications. One area of focus is the development of novel resin materials with enhanced selectivity, capacity, and regeneration efficiency. These advancements could significantly improve the performance of ion exchange systems and reduce operational costs.

Another exciting prospect is the integration of smart technologies and artificial intelligence into ion exchange systems. These innovations could enable real-time monitoring and optimization of the treatment process, leading to improved efficiency and reduced resource consumption. Additionally, there is growing interest in developing hybrid systems that combine ion exchange with other advanced treatment technologies, such as electrochemical processes or catalytic reduction.

"Research indicates that next-generation ion exchange resins could improve contaminant removal efficiency by up to 50% while reducing regeneration frequency by 30%, potentially revolutionizing the field of effluent decontamination."

| Future Trend | Potential Impact | Timeline |

|---|---|---|

| Novel Resin Materials | Improved efficiency, reduced costs | 3-5 years |

| Smart Monitoring Systems | Optimized performance, predictive maintenance | 2-3 years |

| Hybrid Treatment Technologies | Enhanced treatment capabilities | 5-10 years |

| Sustainable Regeneration Methods | Reduced environmental impact | 3-7 years |

| Nanotechnology Integration | Increased selectivity and capacity | 7-10 years |

In conclusion, ion exchange technology plays a crucial role in modern effluent decontamination systems, offering a highly efficient and versatile solution for removing a wide range of contaminants from industrial and municipal wastewater. Its ability to selectively target specific pollutants, coupled with its relatively low operational costs and minimal environmental impact, makes it an invaluable tool in the fight against water pollution.

As we've explored throughout this article, ion exchange systems offer numerous advantages in effluent treatment, from their high removal efficiency to their compatibility with other treatment technologies. While challenges such as resin regeneration and fouling exist, ongoing research and technological advancements continue to address these limitations, paving the way for even more effective and sustainable water treatment solutions.

The future of ion exchange technology in effluent decontamination looks bright, with promising developments in resin materials, smart systems, and hybrid technologies on the horizon. As water scarcity and pollution continue to be pressing global issues, the role of ion exchange in ensuring clean and safe water resources is likely to become even more critical.

By leveraging the power of ion exchange technology, industries and municipalities can not only meet stringent regulatory requirements but also contribute to the broader goal of environmental protection and sustainable water management. As we move forward, the continued evolution of ion exchange technology will undoubtedly play a pivotal role in shaping the future of effluent decontamination and water treatment strategies worldwide.

External Resources

Ion Exchange Technology – Envirogen Group – This resource provides detailed information on how ion exchange technology works, including the process of removing dissolved and ionised impurities in water, and various applications such as water softening and demineralisation/deionisation.

Chapter 08- Ion Exchange, Water Demineralization & Resin Testing – Water Technologies – This chapter covers the basics of ion exchange water treatment systems, including their history, advantages, limitations, and classifications of ion exchange resins, which is crucial for understanding their role in effluent decontamination.

Ion Exchange Water Treatment Systems – Pure Aqua, Inc. – This resource explains how ion exchange systems work, including water softening and deionization, and lists various contaminants that can be removed using these systems. It also details the advantages and maintenance requirements of these systems.

Ion Exchange In Water Treatment | Atlas Scientific – This article provides an overview of the ion exchange process, including the types of ion exchange resins, common methods like water softening and deionization, and the advantages and disadvantages of using ion exchange in water treatment.

Ion Exchange Water Treatment – Veolia Water Technologies – This resource from Veolia Water Technologies discusses the application of ion exchange in various water treatment scenarios, including wastewater treatment, and highlights the different types of resins and their uses.

Ion Exchange for Wastewater Treatment – Lenntech – This page explains how ion exchange is used specifically in wastewater treatment to remove contaminants and improve water quality, including the regeneration process and the types of resins used.

Ion Exchange Systems for Industrial Wastewater Treatment – Samco Technologies – This resource details the application of ion exchange systems in industrial wastewater treatment, including the removal of heavy metals and other contaminants, and discusses the design and operation of these systems.

Ion Exchange Resins for Effluent Treatment – Thermax Global – This page from Thermax Global explains the use of ion exchange resins in effluent treatment, including their types, applications, and the benefits of using these resins in industrial effluent decontamination systems.

Related Contents:

- Safeguarding Health: Advanced Effluent Decontamination Systems

- Effluent Decontamination Systems: Safeguarding Malaysia’s Environment

- Continuous Effluent Decontamination: Protecting Our Environment

- Thermal Treatment: Revolutionizing Effluent Decontamination Systems

- Green Chemistry: Revolutionizing Effluent Decontamination

- Effluent Decontamination: Ensuring Pharmaceutical Safety

- Water Decontamination: Essential Methods for Clean, Safe Water

- Effluent Decontamination: Safeguarding Our Environment

- Thermal Effluent Decontamination: Protecting Our Environment