In the realm of cleanroom technology, maintaining pristine air quality is paramount, especially in industries such as pharmaceuticals, food, biological laboratories, and hospitals. QUALIA's In Situ Filtration System, part of their AirSeriers product line, stands out as a robust solution for negative pressure cleanrooms. Here’s a detailed look at its features and benefits.

Product Features (PF)

Structural Design

- The system comprises a static pressure body, a high-efficiency filter, an exhaust panel, and a control box.

- The chassis is made from high-quality stainless steel with seamless full welding, ensuring good airtightness and resistance to acids, alkalis, and corrosion.

Central Interface Box

- All interfaces are centrally installed in one place, known as the central interface box, ensuring airtightness and ease of operation.

- Includes internal elements such as a scanning handle, dusting/testing port, and disinfection port.

In Situ Disinfection

- Equipped with a disinfection cover that allows for in situ disinfection of the interior of the high-efficiency exhaust port, ensuring convenience and safety.

Filter In Situ Scan Leak Detection

- Features a scanning section that allows for in situ scanning of the filter for leaks without the need for movement, enabling straightforward and highly accurate on-site testing.

Differential Pressure Gauge

- Monitors the pressure differential before and after the filter, indicating when the filter requires replacement.

Airtightness and Pressure Resistance

- Meets technical specifications and exhaust device standards at pressures no less than -1000Pa with a leak rate of less than 0.1% per minute.

- Tested at pressures of ≥±2500Pa and maintained for 10 minutes without significant deformation.

Installation Methods

- Offers ceiling and sidewall installation options, with typical side-mounting in hospital negative pressure wards and flexible mounting in other cleanrooms.

Optional Accessories

- Can be equipped with a bio-seal valve, ultraviolet germicidal lamps, and various exhaust panel styles to meet specific requirements.

Key Performance Indicators

| Feature | Description |

|---|---|

| Filter Efficiency | Achieves ≥99.99% efficiency at (0.3~0.5) μM particle size |

| Rated Air Volume | Ranges from 250m³/h to 2500m³/h, varying according to the model |

| Filter Resistance | Initial resistance of the high-efficiency filtering stage is ≤250Pa |

| Chassis Airtightness | Unit leakage rate is ≤0.1% per minute at +1000Pa pressure |

| Chassis Pressure Resistance | Tested at pressures of ≥±2500Pa without significant deformation |

| Leak Detection Method | Allows for manual scanning leak detection on-site |

Application Areas

QUALIA's In Situ Filtration System is designed for various high-stakes environments, including:

- Pharmaceutical Laboratories: Ensures air purity critical for drug production.

- Food Laboratories: Maintains clean air standards necessary for food safety.

- Biological Laboratories: Protects against biological contaminants.

- Hospitals: particularly in negative pressure wards to prevent the spread of airborne pathogens.

Operational Benefits

Enhanced Safety

The system prevents polluted indoor air from entering the return/exhaust systems, thereby protecting the environment and ensuring the safety of personnel.

Efficient Maintenance

The central interface box and in situ disinfection features make maintenance and filter replacement convenient and safe. The differential pressure gauge ensures timely filter replacements, optimizing system performance.

Versatile Installation

The flexibility in installation options (ceiling or sidewall) allows for adaptation to various cleanroom configurations, making it a versatile solution for different facilities.

High-Efficiency Filtration

With an efficiency of ≥99.99% at particle sizes of (0.3~0.5) μM, this system provides robust air purification, critical for maintaining the integrity of cleanroom environments.

In conclusion, QUALIA's In Situ Filtration System is a cutting-edge solution for negative pressure cleanrooms, offering unparalleled air purification, ease of maintenance, and adaptability to various industrial settings. Its advanced features and robust construction make it an essential component in ensuring the highest standards of air quality and safety.

Related Contents:

- Revolutionizing Air Filtration: The QUALIA AirSeriers In Situ Filtration System

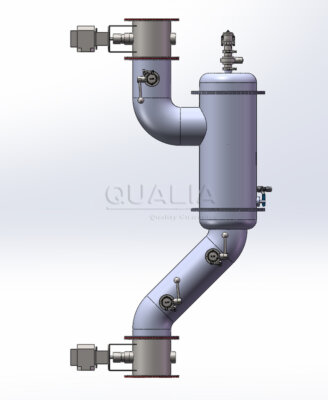

- Advanced Water Treatment with QUALIA’s DOUBLE IN SITU PIPELINE HEPA

- Advanced Safety and Efficiency: QUALIA’s Bag-in Bag-out Filtration Systems

- Revolutionizing Air Filtration: The QUALIA AirSeriers and Bag in Bag Out System

- Enhancing Facility Safety with Bag In Bag Out (BIBO) Systems: A Comprehensive Overview

- Bag In Bag Out Filters: The Ultimate Guide to Safe and Efficient Filter Replacement

- The Ultimate Guide to QUALIA’s Bag-in Bag-out (BIBO) System: Ensuring Safety and Efficiency in Hazardous Environments

- Advanced Features of QUALIA’s BSL-3/BSL-4 Module Laboratories

- How Bag In Bag Out (BIBO) Systems Ensure Safety in Contaminant Removal