Biosafety Level 3 (BSL-3) laboratories play a crucial role in handling dangerous pathogens and conducting critical research. However, the process of obtaining accreditation for these specialized facilities is complex and rigorous. This article will guide you through the step-by-step process of BSL-3 lab accreditation, highlighting key requirements, challenges, and best practices.

Achieving BSL-3 laboratory accreditation involves a comprehensive evaluation of the facility's design, safety protocols, and operational procedures. From initial planning to final certification, each step requires meticulous attention to detail and adherence to strict guidelines. We'll explore the essential components of the accreditation process, including risk assessments, facility design, personnel training, and documentation requirements.

As we delve into the intricacies of BSL-3 laboratory accreditation, it's important to understand that this process is not just about meeting regulatory standards. It's about creating a safe and efficient environment for conducting vital research while protecting laboratory personnel, the community, and the environment. Let's embark on this journey through the BSL-3 laboratory accreditation process and uncover the key steps to success.

The BSL-3 laboratory accreditation process is a rigorous and multifaceted procedure designed to ensure the highest standards of safety and operational excellence in facilities handling potentially lethal biological agents.

What are the initial steps in planning for BSL-3 laboratory accreditation?

The journey towards BSL-3 laboratory accreditation begins long before the first safety inspection. It starts with careful planning and a thorough understanding of the requirements and standards set by regulatory bodies. This initial phase is crucial for laying a solid foundation for the entire accreditation process.

At the outset, facility managers and administrators must conduct a comprehensive needs assessment. This involves evaluating the types of research to be conducted, the pathogens to be handled, and the specific safety measures required. It's also essential to review current guidelines and regulations to ensure compliance from the start.

One of the key aspects of this planning phase is assembling a qualified team to oversee the accreditation process. This team should include biosafety experts, facility managers, researchers, and representatives from relevant regulatory bodies. Their collective expertise will be invaluable in navigating the complex requirements of BSL-3 accreditation.

Proper planning and team assembly are critical first steps in the BSL-3 laboratory accreditation process, setting the stage for successful implementation of safety measures and regulatory compliance.

| Planning Phase Components | Description |

|---|---|

| Needs Assessment | Evaluation of research scope and safety requirements |

| Regulatory Review | Analysis of current guidelines and standards |

| Team Assembly | Formation of a multidisciplinary accreditation team |

| Timeline Development | Creation of a comprehensive project schedule |

The planning phase concludes with the development of a detailed timeline and project plan. This roadmap will guide the facility through each subsequent step of the accreditation process, ensuring that all requirements are met systematically and efficiently.

How does facility design impact BSL-3 laboratory accreditation?

The design of a BSL-3 laboratory is a critical factor in the accreditation process. Every aspect of the facility's layout and infrastructure must be carefully considered to meet stringent safety standards and operational requirements. This includes everything from the basic floor plan to complex air handling systems.

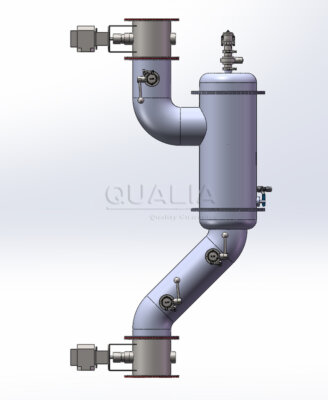

One of the primary considerations in BSL-3 lab design is containment. The facility must be constructed to prevent the release of potentially hazardous materials into the environment. This involves the implementation of airlocks, negative air pressure systems, and HEPA filtration. Additionally, the laboratory must be designed with decontamination in mind, incorporating materials and surfaces that are easy to clean and resistant to the harsh chemicals used in sterilization procedures.

Another crucial aspect of BSL-3 laboratory design is the integration of safety equipment. This includes biosafety cabinets, autoclaves, and emergency shower and eyewash stations. The placement and specification of this equipment must comply with regulatory standards and facilitate safe and efficient laboratory operations.

The design of a BSL-3 laboratory is not just about meeting regulatory requirements; it's about creating a space that inherently promotes safety and facilitates the complex work conducted within its walls.

| Design Element | Requirement |

|---|---|

| Airflow | Directional, inward flow with HEPA filtration |

| Containment | Sealed windows, self-closing doors, airlocks |

| Surfaces | Non-porous, chemical-resistant materials |

| Safety Equipment | Properly placed biosafety cabinets and autoclaves |

Ultimately, the design phase must result in a facility that not only meets current standards but is also flexible enough to adapt to future changes in research needs and safety regulations. This forward-thinking approach is essential for long-term accreditation success.

What are the key safety protocols required for BSL-3 accreditation?

Safety protocols are at the heart of BSL-3 laboratory operations and play a pivotal role in the accreditation process. These protocols encompass a wide range of procedures and practices designed to protect laboratory personnel, the community, and the environment from potential exposure to hazardous biological agents.

One of the fundamental aspects of BSL-3 safety protocols is the proper use of personal protective equipment (PPE). This typically includes disposable gowns, gloves, and respiratory protection. The specific PPE requirements may vary depending on the pathogens being handled and the nature of the work being conducted. Training in the correct use and disposal of PPE is an essential component of the safety protocol.

Another critical element is the implementation of standard operating procedures (SOPs) for all laboratory activities. These SOPs should cover everything from routine experiments to emergency response scenarios. They must be comprehensive, clearly written, and regularly updated to reflect any changes in research practices or safety regulations.

Comprehensive and well-implemented safety protocols are not just a requirement for accreditation; they are the backbone of a safe and effective BSL-3 laboratory environment.

| Safety Protocol Element | Description |

|---|---|

| PPE Requirements | Specification of required protective gear |

| SOPs | Detailed procedures for all laboratory activities |

| Decontamination Procedures | Methods for sterilizing equipment and work areas |

| Emergency Response Plans | Protocols for handling accidents and incidents |

The accreditation process will closely scrutinize these safety protocols, ensuring that they are not only in place but also effectively implemented and followed by all laboratory personnel. Regular training and drills are essential to maintain compliance and readiness.

How is personnel training and certification integrated into the accreditation process?

Personnel training and certification are integral components of the BSL-3 laboratory accreditation process. The highly specialized nature of work conducted in these facilities requires a workforce that is not only skilled in scientific procedures but also deeply versed in safety protocols and emergency procedures.

The training program for BSL-3 laboratory personnel typically begins with a comprehensive orientation covering the basics of biosafety, risk assessment, and laboratory-specific procedures. This is followed by more specialized training tailored to the specific pathogens and research activities conducted in the facility. Hands-on training in the use of safety equipment, such as biosafety cabinets and autoclaves, is also a crucial part of the program.

Certification of personnel is an ongoing process that doesn't end with initial training. Regular refresher courses and competency assessments are necessary to ensure that all staff members maintain their skills and stay updated on the latest safety practices and regulatory requirements.

Effective personnel training and certification programs are not just about meeting accreditation standards; they're about fostering a culture of safety and competence that is essential for BSL-3 laboratory operations.

| Training Component | Description |

|---|---|

| Biosafety Basics | Foundational knowledge of safety principles |

| Pathogen-Specific Training | Specialized instruction for specific biological agents |

| Equipment Operation | Hands-on training with laboratory equipment |

| Emergency Procedures | Drills and simulations for incident response |

The accreditation process will evaluate not only the content of the training program but also its effectiveness in preparing personnel for the challenges of working in a BSL-3 environment. Documentation of training completion and ongoing competency assessments will be crucial for demonstrating compliance.

What role does documentation play in the BSL-3 accreditation process?

Documentation is a critical component of the BSL-3 laboratory accreditation process, serving as a record of compliance and a roadmap for ongoing operations. Proper documentation demonstrates to accrediting bodies that the facility is adhering to all required standards and protocols.

One of the primary forms of documentation is the Biosafety Manual, which outlines all safety procedures, risk assessments, and emergency response plans. This comprehensive document should be regularly updated to reflect any changes in laboratory practices or regulatory requirements. Standard Operating Procedures (SOPs) for all laboratory activities must also be meticulously documented and readily accessible to all personnel.

Maintenance records for all equipment, including biosafety cabinets, HVAC systems, and autoclaves, are another crucial aspect of documentation. These records should detail regular inspections, repairs, and certifications, providing a clear history of the facility's commitment to maintaining safe and functional equipment.

Comprehensive and well-maintained documentation is not just a bureaucratic exercise; it's a vital tool for ensuring consistency, traceability, and continuous improvement in BSL-3 laboratory operations.

| Documentation Type | Purpose |

|---|---|

| Biosafety Manual | Comprehensive guide to safety procedures |

| SOPs | Detailed instructions for laboratory activities |

| Maintenance Records | History of equipment upkeep and certification |

| Training Logs | Record of personnel training and competency |

During the accreditation process, auditors will carefully review all documentation to ensure that it is complete, up-to-date, and reflective of actual laboratory practices. The ability to quickly produce required documentation is often seen as an indicator of a well-organized and compliant facility.

How are risk assessments conducted and integrated into the accreditation process?

Risk assessments are a fundamental component of the BSL-3 laboratory accreditation process, serving as the foundation for safety protocols and operational procedures. These assessments involve a systematic evaluation of potential hazards associated with the specific pathogens and research activities conducted in the facility.

The risk assessment process typically begins with identifying all biological agents to be handled in the laboratory and evaluating their potential for causing harm. This includes considering factors such as transmission routes, infectious dose, and available treatments or preventive measures. The assessment also takes into account the specific procedures to be performed and the potential for aerosol generation or other modes of exposure.

Once risks are identified, the next step is to develop and implement appropriate control measures. These may include engineering controls (such as biosafety cabinets), administrative controls (like SOPs), and personal protective equipment. The effectiveness of these controls must be regularly evaluated and adjusted as needed.

Comprehensive risk assessments are not just a requirement for accreditation; they are an ongoing process that forms the basis for safe and effective BSL-3 laboratory operations.

| Risk Assessment Component | Description |

|---|---|

| Hazard Identification | Cataloging of biological agents and procedures |

| Risk Evaluation | Analysis of potential harm and exposure routes |

| Control Measures | Implementation of safety protocols and equipment |

| Ongoing Monitoring | Regular review and adjustment of risk mitigation strategies |

The accreditation process will closely examine the facility's risk assessment procedures, ensuring that they are thorough, well-documented, and effectively integrated into all aspects of laboratory operations. This includes verifying that all personnel are trained in risk assessment principles and that risk assessments are regularly updated to reflect changes in research activities or emerging knowledge about pathogens.

What are the final steps in achieving BSL-3 laboratory accreditation?

As the BSL-3 laboratory nears the end of its accreditation journey, several critical steps remain to ensure full compliance and readiness for official certification. These final stages are crucial in demonstrating that the facility meets all necessary standards and is prepared for safe and effective operation.

One of the key final steps is a comprehensive facility inspection. This typically involves a team of experts who will scrutinize every aspect of the laboratory, from physical infrastructure to operational procedures. They will verify that all safety equipment is properly installed and functioning, that containment measures are effective, and that all documentation is complete and up-to-date.

Another important element is the validation of all critical systems and equipment. This includes testing of the HVAC system to ensure proper air handling and filtration, verification of biosafety cabinet performance, and confirmation that all decontamination procedures are effective. These validations often involve specialized testing procedures and may require the expertise of external consultants.

The final stages of BSL-3 laboratory accreditation are not just about passing an inspection; they're about demonstrating a comprehensive culture of safety and compliance that will endure long after the accreditation is granted.

| Final Accreditation Step | Description |

|---|---|

| Facility Inspection | Comprehensive review of physical and operational elements |

| Systems Validation | Testing and verification of critical equipment and procedures |

| Documentation Review | Final check of all required records and manuals |

| Personnel Readiness | Confirmation of staff training and competency |

The accreditation process concludes with a final review of all documentation and a series of interviews with key personnel to ensure that they are fully prepared to operate the BSL-3 facility safely and effectively. Once all requirements are met, the accrediting body will issue the official certification, often with recommendations for ongoing monitoring and improvement.

In conclusion, the BSL-3 laboratory accreditation process is a complex and rigorous journey that requires meticulous planning, execution, and ongoing commitment to safety and excellence. From the initial planning stages through facility design, implementation of safety protocols, personnel training, and final certification, each step plays a crucial role in creating a laboratory environment that can safely handle dangerous pathogens and conduct critical research.

The importance of this process cannot be overstated. BSL-3 laboratories are at the forefront of studying and combating some of the most challenging diseases facing humanity. By ensuring that these facilities meet the highest standards of safety and operational excellence, the accreditation process not only protects laboratory workers and the surrounding community but also enables vital scientific progress.

As we've explored in this article, achieving and maintaining BSL-3 accreditation is an ongoing process that requires constant vigilance, adaptation to new standards, and a deep commitment to safety culture. It's a testament to the dedication of scientists, biosafety professionals, and regulatory bodies working together to advance our understanding of dangerous pathogens while prioritizing safety above all else.

For those embarking on the journey of BSL-3 laboratory accreditation, remember that while the process is challenging, it is also an opportunity to create a facility that stands at the pinnacle of scientific capability and safety. With careful planning, attention to detail, and a commitment to continuous improvement, your laboratory can join the ranks of world-class BSL-3 facilities, contributing to vital research while maintaining the highest standards of safety and regulatory compliance.

External Resources

- National Institutes of Health Biosafety Level 3-Laboratory Certification Requirements – This document outlines the detailed requirements for the certification of Biosafety Level 3 (BSL-3) laboratories, including administrative controls, engineering controls, and the necessity for annual re-certification.

- BSL-3 and ABSL-3 HVAC System Requirements – Part II – This resource provides specific guidelines on the HVAC system requirements for BSL-3 and Animal BSL-3 (ABSL-3) facilities, including testing and performance verification methodologies.

- Commissioning Certification, BSL-3 Requirements | TSS – This page describes the services offered by TSS for BSL-3 testing, certification, and performance verification, ensuring that facilities operate reliably and meet regulatory requirements.

- Biosafety in Microbiological and Biomedical Laboratories (BMBL) 6th Edition – Although not directly linked, this resource is often cited in discussions about BSL-3 laboratory accreditation. It provides comprehensive guidelines on biosafety levels, including BSL-3, and is a critical reference for laboratory safety.

Related Contents:

- Biosafety Cabinet Certification: Why It’s Crucial

- Mobile BSL Lab Certification: Step-by-Step Guide

- BSL-3 Certification: Lab Renewal Process Guide

- BSL-3 Standards: Global Regulatory Comparison

- BSL-3/4 Biosafety Training: Comprehensive Guide

- BSL-3 Lab Certification: Key Requirements

- BSL-3 Lab Documentation: Complete Requirements

- BSL-3 Lab Audits: Best Practices for Compliance

- BSL-3 Lab Training: Comprehensive Program Outline