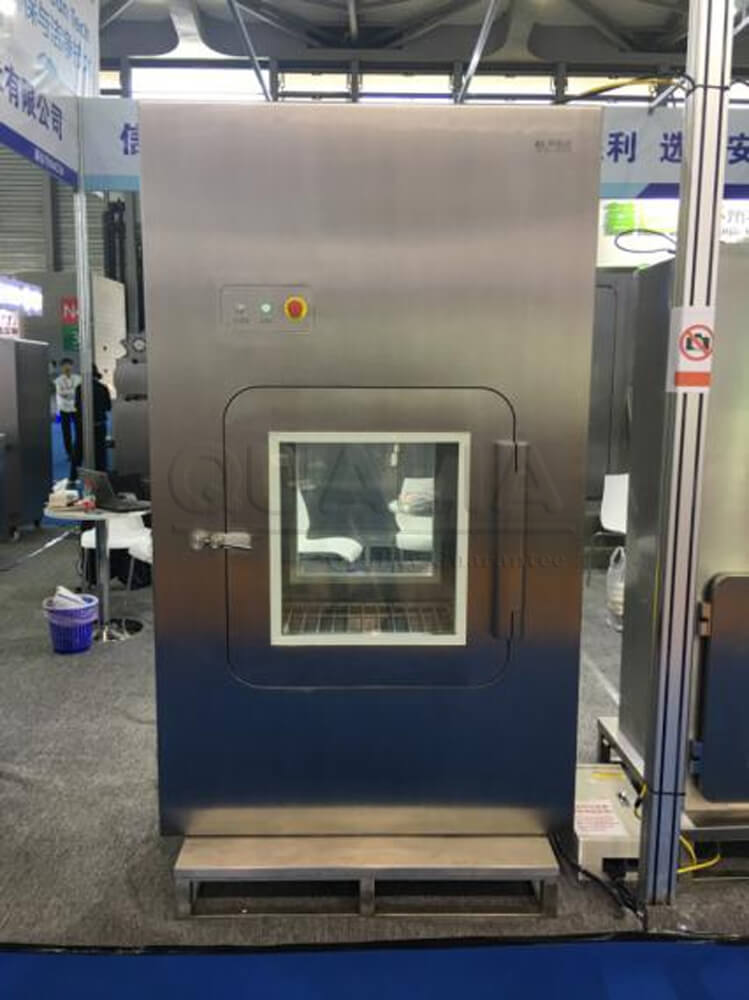

What is the Biosafety Pass Box?

The Bio-safety Pass Box is a device used in laboratory or medical environments to control the transfer of items between areas of different biological safety levels by establishing a physical barrier, preventing contamination of clean areas. The interior of the pass box is usually equipped with disinfection facilities, such as ultraviolet disinfection lamps or chemical disinfectants, to disinfect items and ensure biosafety during the transfer process. Furthermore, some advanced pass boxes are equipped with VHP (vaporized hydrogen peroxide) disinfection ports, which can be connected to a VHP generator for more thorough sterilization. VHP is an effective disinfection method that produces a hydrogen peroxide mist, thoroughly killing a wide range of microorganisms, including bacteria, viruses, fungi, and spores. This design allows the pass box to efficiently sterilize transported objects without opening the door, making it very suitable for laboratories and production environments with high biological safety level requirements.

Connected Biosafety Passbox Sterilization

with Mechanical Seal APR Door

QUALIA vs. OTHERS

| Feature | Qualia | Competitor |

|---|---|---|

| Seal Integrity | ±2000Pa with <0.5% Vol/h decay over 20 minutes | 100Pa with ≤0.5% Vol/h decay |

| Mechanical/Inflatable Seal | EPDM (Ethylene Propylene Diene Monomer) 6±5° shoreA | Silicone Rubber |

| Seal Service Life | ≥5 years | ≤1-3 years |

| Seal Strip Corner Radius | R95 | R100 |

Product Features

Stainless Steel Inner Circle Details

with Mechanical Seal APR Door Handle

- UV Lamp Compatibility: Ready for UV lights that withstand VHP disinfection on all three sides.

- Sealing Options: Inflatable seal and mechanical compression; inflatable variant uses high-density EPDM from the Netherlands with a hardness of 60±5° Shore A and features concealed inflation tubing.

- Seal Integrity: Complies with pressure decay standards, maintaining less than 0.5% Vol/h decay at ±2000Pa over 20 minutes for biosafety compliance.

- VHP Generator: Optional; employs a fully vaporizing mechanism with multi-channel labyrinth module to prevent sterilization condensation and fogging (link to product).

- BMS Communication: Facilitates integration with BMS systems for online and remote printing, as well as data storage capabilities.

Dual Chamber Biosafety Passbox Sterilization

with Mechanical Seal APR Door Handle

- Sterilization Temperature Control: Optional feature that keeps temperature variation within ≤3℃, suitable for delicate transfers like serum that require specific temperature settings.

- Functionality Switch: Optional; offers a choice between VHP sterilization and standard self-cleaning UV modes via touchscreen.

- Door Construction: Both sides made with fully welded 3.0mm stainless steel and middle sections fitted with double-layer 5mm tempered glass.

- Safety Design: Doors have concentric circle corners with inner rounded arc welds and thorough sanding to ensure user safety and minimize breakage risk.

Biosafety Pass Box Gallery

Related Contents:

- Double-Chamber VHP Passbox: Enhancing Efficiency and Flexibility

- Ensuring Safety with Bag-in/Bag-out: The Definitive Guide to Hazardous Filter Replacement

- What is the process of bag in bag out?

- What is the HS Code for “Bag in Bag Out”?

- Navigating Biocontainment: The Critical Differences Between BSL-3 and BSL-4 Labs

- Introducing Our Custom-Designed Dry Isolation Weighing Chamber for European Clients

- Introducing Qualia: Advanced OEB5 Grade Protection with Bag-In Bag-Out (BIBO) System

- Understanding the Differences Between Stationary and Mobile BSL-3/BSL-4 Laboratories

- Join Qualia at ACHEMA 2024 in Frankfurt, Germany